Applicable Environment

-

Tools and Instruments

Tools and Instruments -

Control System

Control System -

Spraying Tools

Spraying Tools -

Successful Injection

Successful Injection -

Car Shop

Car Shop -

Tire Pressure

Tire Pressure

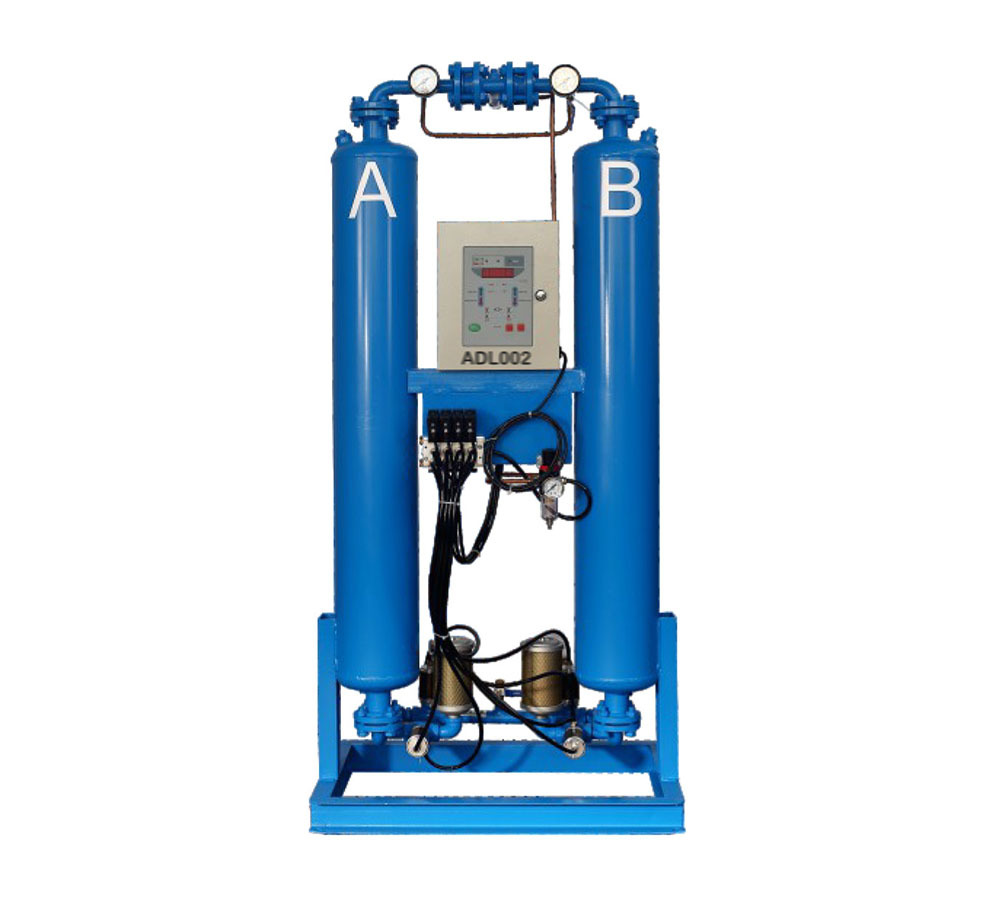

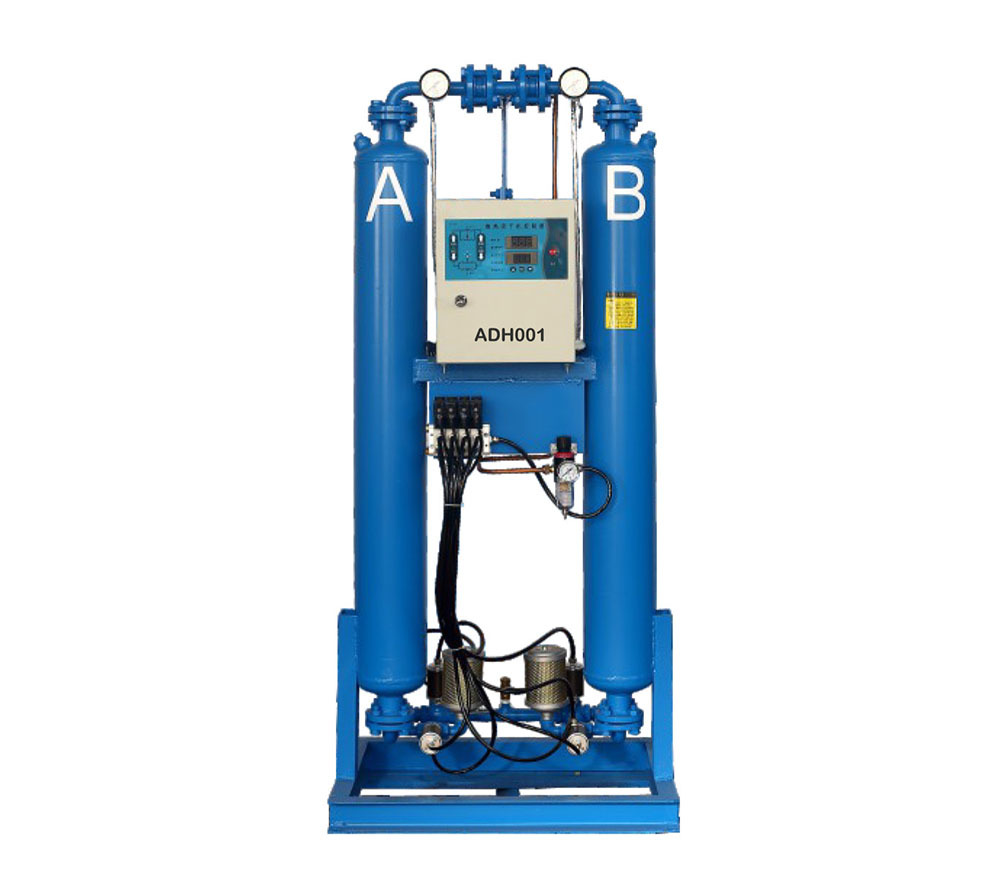

Product Introduction:

Working Principle: By organically combining refrigeration dryers and adsorption dryers, it integrates the advantages of both to achieve deep drying of compressed air.

Workflow: Compressed air delivered from the air compressor through the rear cooler first undergoes heat exchange with dried low-temperature compressed air in the heat exchanger to lower its temperature. Then, it enters the evaporator, where it is further cooled to about 2℃. At this dew point, most of the water in the compressed air has become liquid and is discharged. The compressed air with minimal water content then enters the adsorption tower for further drying and water removal. Finally, the low-temperature dried compressed air enters the heat exchanger, cooling the incoming high-temperature humid air, while its own temperature rises. A small portion of the warmed compressed air is used as regeneration gas for the adsorbent, improving regeneration efficiency and lowering energy consumption.

Operating Requirements: Air inlet temperature: 0-45℃, operating pressure 0.6~1.0MPa (higher pressure available upon request), pressure dew point -20~-70℃, PLC electronic control.

Product Features:

1. Integrated structure, no foundation installation required.

2. High-quality compressed air, low dew point, reaching -20~-70℃

3. Air consumption 3-5%, adjustable.

4. Long desiccant service life, generally over 3 years.

5. Microcomputer program control, easy operation.

Operating Conditions:

1. Operating pressure: 0.6~1.0MPa

2. Pressure dew point -20~-70℃

3. Air inlet temperature 0~45℃

4. Pressure drop ≤0.25MPa

RC Series Combined Dryer Model Parameters

|

Model |

Air Processing

Capacity m3 /min

|

Power Supply

V/50Hz

|

Pipe Diameter

|

Dimensions mm |

Weight kg |

||

|

RC0030 |

3.8 |

220/50 |

G1 |

1150 |

700 |

1800 |

220 |

|

RC0040 |

5.5 |

220/50 |

G1 1/2 |

1300 |

900 |

1800 |

370 |

|

RC0060 |

6.8 |

220/50 |

G1 1/2 |

1300 |

1000 |

1800 |

400 |

|

RC0080 |

8.8 |

20/50 |

G2 |

1400 |

1060 |

2000 |

600 |

|

RC0100 |

11.5 |

220/50 |

G2 |

1400 |

1160 |

1900 |

650 |

|

RC0120 |

14 |

380/50 |

G2 1/2 |

1600 |

1160 |

1900 |

800 |

|

RC0150 |

15 |

380/50 |

G2 1/2 |

1600 |

1260 |

2000 |

900 |

|

RC0200 |

22.8 |

380/50 |

DN80 |

2000 |

1500 |

2050 |

1500 |

|

RC0250 |

28.5 |

380/50 |

DN80 |

2000 |

1700 |

2180 |

1700 |

|

RC0300 |

35 |

380/50 |

DN80 |

2000 |

1700 |

2220 |

2100 |

|

RC0400 |

45 |

380/50 |

DN100 |

2100 |

2000 |

2400 |

2500 |

|

RC0500 |

55 |

380/50 |

DN100 |

2200 |

2100 |

2500 |

3100 |

|

RC0600 |

65 |

380/50 |

DN125 |

2400 |

2200 |

2650 |

3500 |

|

RC0800 |

85 |

380/50 |

DN150 |

2600 |

2600 |

2900 |

4200 |

|

RC1000 |

105 |

380/50 |

DN150 |

3000 |

2800 |

3000 |

5200 |

|

RC1200 |

120 |

380/50 |

DN200 |

3200 |

3000 |

3000 |

5800 |

|

RC1600 |

160 |

380/50 |

DN200 |

3800 |

3000 |

3000 |

7600 |

|

RC2000 |

200 |

380/50 |

DN250 |

4200 |

3500 |

3000 |

9500 |

Note:

1. The capacity in the table is calculated based on standard conditions (inlet pressure 0.7Mpa, inlet temperature 38℃);

2. When the actual conditions are different from the standard conditions, the correction coefficient should be calculated according to the pressure correction formula.

Pressure correction formula: Pressure correction coefficient = Actual inlet pressure / Standard condition inlet pressure;

3. 304 and 316 materials are available upon request.

4. Operating pressure within 4.5MPa is available upon request.

5. Pressure dew point -20~-70℃