Applicable Environment

-

Tools and instruments

Tools and instruments -

Control system

Control system -

Spraying tools

Spraying tools -

Successful injection

Successful injection -

Auto shop

Auto shop -

Tire pressure

Tire pressure

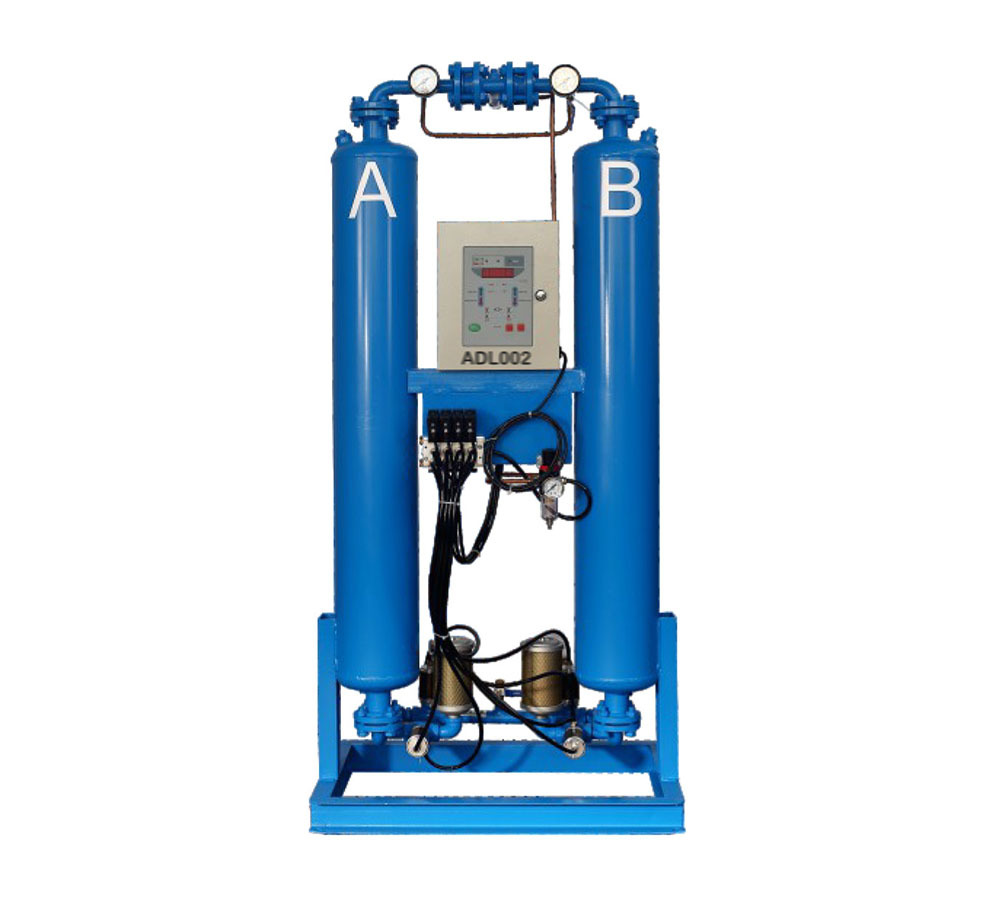

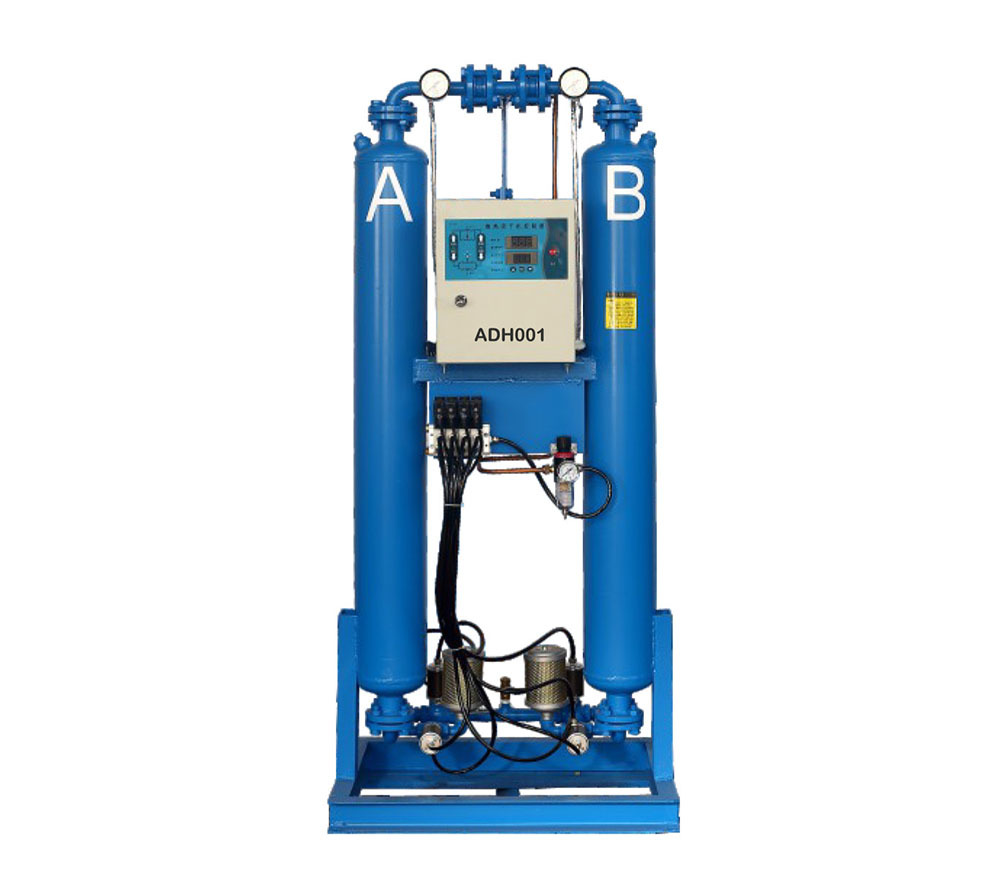

Product Introduction

■ PLC Control

The controller uses our self-developed PLC controller (patented product), making the equipment operation more stable, more reliable, and stronger anti-interference ability.

■ Principle

Adsorption drying process: The moist compressed air flows through the adsorption tower filled with high-performance adsorbent. The moisture in the compressed air is absorbed by the adsorbent to be dried and flows to the air-using terminal for use at the air-using point.

Regeneration process: This series of dryers uses a high-pressure blower to blow ambient air (as regeneration airflow) into the heater jacket and flow through the adsorbent that needs to be desorbed. The moisture is removed from the adsorption cylinder and discharged into the atmosphere, utilizing the principle of adsorbent desorption at high temperatures.

■ Advantages

1. Low regeneration air volume: Air from the external environment is blown in as regeneration air using a high-pressure blower, consuming only a small amount of dry finished compressed air for cooling.

2. Uses a high-reliability, long-life, low-noise high-pressure blower.

3. Uses a high-performance PLC as the control host, with strong anti-interference ability, ensuring stable equipment operation, and allowing local or remote monitoring of the equipment's operating status (communication interfaces can be provided for customers).

4. Based on the adsorption characteristics of activated alumina and molecular sieves, the company's self-developed layering technology allows the air to first undergo preliminary drying with activated alumina, reducing the moisture content before undergoing deep drying with molecular sieves to achieve low dew point air quality.

Working Conditions and Technical Indicators

● Regeneration air volume (Purge Air): ≤1%

● Working pressure (Inlet pressured): 0.6~1.0Mpa

● Inlet oil content (Inlet oil content): ≤0.1 mg/m³

● Pressure dew point (Dew point): -20°C - -40°C

● Standard working cycle (Working periods): 8 hours

● Inlet temperature (Inlet temperature): 0°C~45°C

Model Specifications and Performance Parameters

|

Model |

Flow Rate Nm³/min |

Blower Power |

Electric Heater KW |

Cooling Water |

Air Interface Pipe Diameter |

Dimensions mm |

Weight |

Power Supply V/Hz |

||

|

L |

W |

H |

||||||||

|

ADG0150 |

16 |

2.2 |

6.5 |

4 |

DN65 |

1600 |

1200 |

2230 |

985 |

380/50V |

|

ADG0200 |

22.8 |

3 |

10 |

6 |

DN80 |

1700 |

1400 |

2300 |

1100 |

|

|

ADG0250 |

28.5 |

3 |

10 |

8 |

DN80 |

1700 |

1500 |

2300 |

1200 |

|

|

ADG0300 |

33 |

4.3 |

12 |

8 |

DN80 |

1700 |

1650 |

2600 |

1335 |

|

|

ADG0400 |

45 |

5.5 |

15 |

10 |

DN100 |

1800 |

1800 |

2600 |

2430 |

|

|

ADG0500 |

55 |

7.5 |

18 |

10 |

DN125 |

1800 |

1800 |

2700 |

3000 |

|

|

ADG0600 |

65 |

7.5 |

20 |

10 |

DN125 |

2000 |

1800 |

2750 |

3600 |

|

|

ADG0800 |

85 |

11 |

25 |

12 |

DN125 |

2400 |

2000 |

2930 |

3800 |

|

|

ADG1000 |

105 |

12.5 |

30 |

14 |

DN150 |

2800 |

2000 |

2950 |

4660 |

|

| ADG1200 | 120 | 12.5 | 35 | 18 | DN200 | 2600 | 2400 | 3000 | 6000 | |

| ADG1500 | 150 | 15 | 45 | 18 | DN200 | 3000 | 2500 | 3200 | 7500 | |

| ADG2000 | 200 | 18.5 | 80 | 22 | DN200 | 3560 | 2550 | 3200 | 8500 | |

| ADG2500 | 250 | 22 | 120 | 26 | DN250 | 3800 | 2800 | 3300 | 10000 | |

| ADG3000 | 300 | 30 | 150 | 30 | DN250 | 4000 | 2900 | 3300 | 11500 | |

| ADG3500 | 350 | 40 | 200 | 40 | DN300 | 4500 | 2900 | 3300 | 13000 | |

| ADG4000 | 400 | 50 | 250 | 50 | DN300 | 4800 | 2900 | 3300 | 15000 | |

|

ADG4500 |

450 |

70 |

300 |

55 |

DN400 |

5500 |

2900 |

3000 |

18000 |

|