Applicable Environment

-

Tools and instruments

Tools and instruments -

Control system

Control system -

Spraying tools

Spraying tools -

Successful injection

Successful injection -

Auto shop

Auto shop -

Tire pressure

Tire pressure

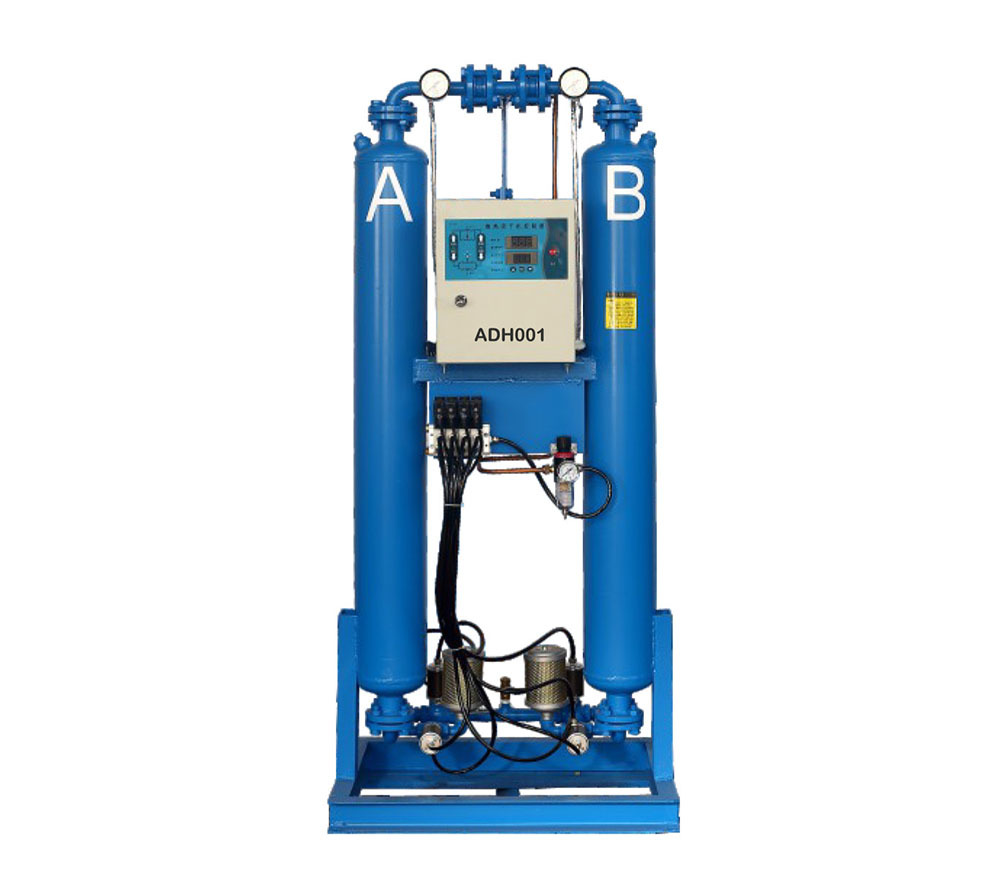

Product Introduction:

Working Principle: Utilizing pressure swing adsorption regeneration cycle, the compressed air is exchanged through two drying cylinders (towers) filled with adsorbent (A and B). One cylinder (tower) adsorbs water vapor under high pressure (working pressure), while the other is desorbed under low pressure (atmospheric pressure), and they switch according to a set time program.

The working principle of a heatless regenerative adsorption dryer is based on Pressure Swing Adsorption (PSA). This device has short adsorption and desorption times, and the adsorption heat generated during the adsorption process is mainly present in the adsorption bed, while the desorption process is approximately isothermal. In the desorption process, a certain amount of finished gas is consumed for adsorbent regeneration, but the overall energy consumption is less than that of a heat-regenerated adsorption dryer.

Short adsorption and desorption times, no external heating required, directly using finished gas to backflush the adsorbent for regeneration.

Basic Structure: Consists of adsorption tanks (towers), adsorbent, switching device, regeneration pipeline, muffler, and controller.

(1) Adsorption Tank

The adsorption tank is a pressure vessel containing the adsorbent. Diffusers are installed at the inlet and outlet openings of the adsorption tank to ensure uniform distribution of air across the cross-section of the tank. The diffusers are mesh filters installed at the inlet and outlet of the adsorption tank. The gas diffusion mesh at the bottom of the equipment is welded inside the adsorption tank.

(2) Adsorbent

Activated alumina—Strong and stable adsorption performance, does not deliquesce when encountering moisture, and has high crush strength and abrasion resistance, suitable for a wide range of applications. Usually used for pressure dew points of -40℃.

Molecular sieve—Due to its good drying performance at a relative humidity below 20%, it is often used as a desiccant for deep drying. Usually used for pressure dew points of -70℃.

Our company uses activated alumina or molecular sieve as adsorbent materials, increasing operational reliability. Compared to many other adsorbents, its advantages include:

1) Incoming moisture has no effect on it (water resistance)

2) High friction resistance

3) Maintains high water absorption capacity

(3) Switching Device

The switching of the adsorption tanks is accomplished by four pneumatic valves installed in the pipeline. The pneumatic valves are operated by a double-piston pneumatic mechanism. The pneumatic drive mechanism is controlled by a two-position four-way solenoid valve.

(4) Regeneration Pipeline

Regeneration air is discharged through two pneumatic valves installed on the exhaust pipe. The pneumatic valves are operated by a double-piston pneumatic mechanism. The pneumatic drive mechanism is controlled by a two-position four-way solenoid valve.

(5) Muffler

The muffler is installed at the end of the exhaust pipe to reduce the noise of the regeneration gas from the adsorption tank.

(6) Controller

The system control uses a PLC programmable controller, configured with a large-screen Chinese LCD display, automatic detection and control, with complete and simple functions. Touch-key setting parameters, all parameters should be displayed on the screen.

Workflow:

1. Adsorption—Wet air enters the A drying cylinder (tower) from the lower piping system through valve A1, flows upward through the adsorbent layer, and the dried compressed air is discharged from the upper piping system.

2. Regeneration—Part of the dry air (approximately 10%) enters the B drying cylinder (tower) through the upper piping system and the regeneration gas regulating valve. The depressurized dry air (called regeneration gas) flows downwards to desorb and regenerate the adsorbent in the B drying cylinder (tower), restoring the drying capacity of the adsorbent. The regeneration gas is discharged to the atmosphere through the lower piping system, valve B2, and the muffler.

3. Pressure equalization—After the adsorbent regeneration is complete, valve B2 is closed, and the B drying cylinder (tower) is pressurized to the online working pressure, ready for switching.

4. Switching -- Open the lower pipe system B1 valve, close the A1 valve, open the A2 valve. The A and B drying cylinders (towers) are switched. The B cylinder (tower) enters adsorption and the A cylinder (tower) depressurizes and regenerates. The working order and working time are automatically controlled by the controller.

Operating Requirements: Inlet temperature 0~45℃, ambient temperature -20~40℃, inlet oil content ≤0.5ppm, pneumatic valve air pressure ≥0.4MPa.

Selection: Athermal regenerative adsorption dryers are small, light, and easy to maintain, with air consumption ≤14%, and atmospheric pressure dew point can reach -50~-30℃. However, the processing flow rate is small, so it is suitable for occasions with small air volume but high drying requirements.

Model Parameters

|

Model |

Air Processing |

Air Pipe Diameter | Dimensions L X W X H mm |

Weight kg |

||

|

ADL0005 |

0.8 |

G1/2 |

600 |

350 |

1500 |

70 |

|

ADL001 |

1.8 |

G3/4 |

650 |

450 |

1500 |

80 |

|

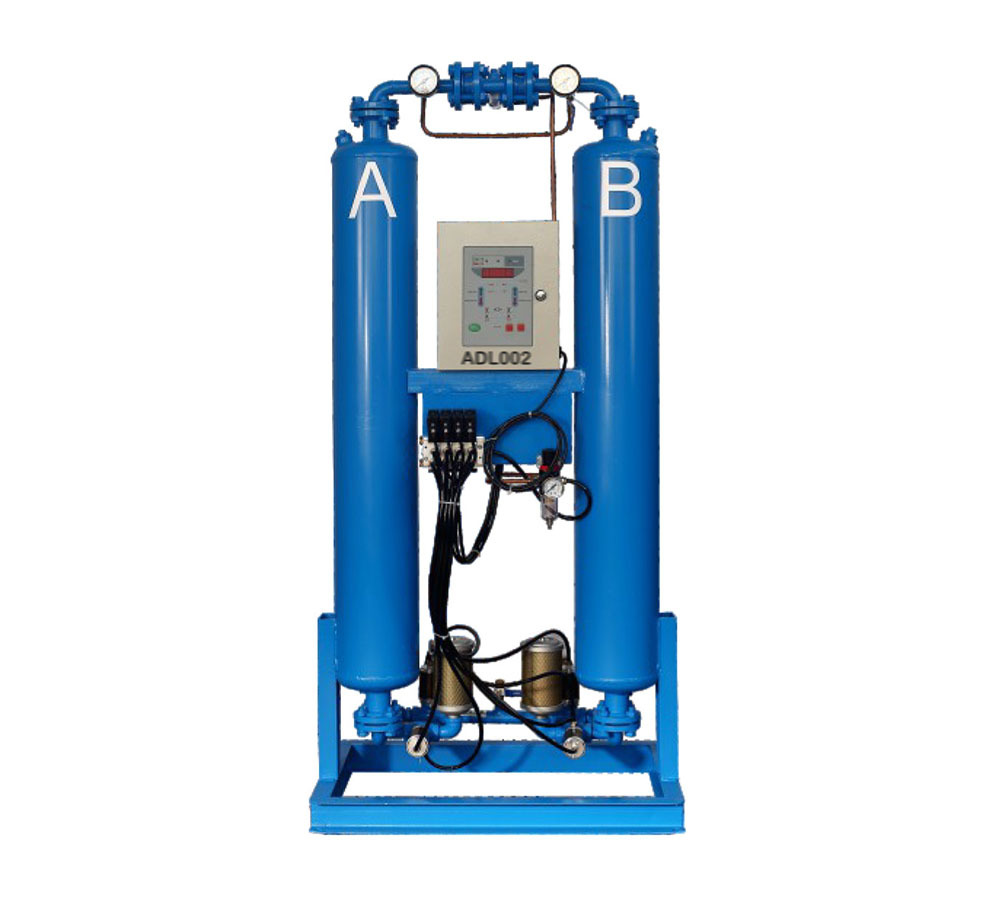

ADL002 |

2.8 |

G3/4 |

700 |

450 |

1500 |

100 |

|

ADL003 |

3.8 |

G1 |

900 |

480 |

1600 |

130 |

|

ADL004 |

5.5 |

G1 1/2 |

1000 |

650 |

1750 |

250 |

|

ADL006 |

6.8 |

G1 1/2 |

1000 |

700 |

1800 |

280 |

|

ADL008 |

8.8 |

G2 |

1100 |

700 |

1900 |

450 |

|

ADL010 |

11.5 |

G2 |

1100 |

650 |

2050 |

500 |

|

ADL012 |

14 |

G2 1/2 |

1200 |

850 |

2200 |

550 |

|

ADL015 |

16 |

G2 1/2 |

1200 |

850 |

2200 |

580 |

|

ADL020 |

22.8 |

DN80 |

1400 |

1000 |

2350 |

860 |

|

ADL025 |

28.5 |

DN80 |

1400 |

1000 |

2500 |

1200 |

|

ADL030 |

35 |

DN80 |

1750 |

1100 |

2500 |

1600 |

|

ADL040 |

45 |

DN100 |

1700 |

1100 |

2600 |

1900 |

|

ADL050 |

55 |

DN100 |

1900 |

1200 |

2800 |

2300 |

|

ADL060 |

65 |

DN125 |

2000 |

1300 |

2800 |

2800 |

|

ADL080 |

85 |

DN150 |

2200 |

1600 |

2900 |

3400 |

|

ADL100 |

105 |

DN150 |

2600 |

1600 |

2960 |

4100 |

|

ADL120 |

120 |

DN200 |

3200 |

1600 |

3000 |

4500 |

|

ADL160 |

160 |

DN200 |

3800 |

1800 |

3000 |

6000 |

|

ADL200 |

200 |

DN250 |

4200 |

2000 |

3000 |

7500 |

Note:

1. The processing capacity in the table is calculated based on standard operating conditions (inlet pressure 0.7Mpa, inlet temperature 38℃);

2. When the actual operating conditions are different from the standard operating conditions, the correction coefficient should be calculated according to the pressure correction formula.

Pressure correction formula: Pressure correction coefficient = actual inlet pressure / standard operating condition inlet pressure;

3. 304 and 316 materials are available upon request.

4. Working pressure within 4.5MPa is available upon request.

5. Pressure dew point -20~-70℃