Applicable environment

-

Tools and equipment

Tools and equipment -

Control system

Control system -

Spraying tools

Spraying tools -

Injection successful

Injection successful -

Car shop

Car shop -

Tire pressure

Tire pressure

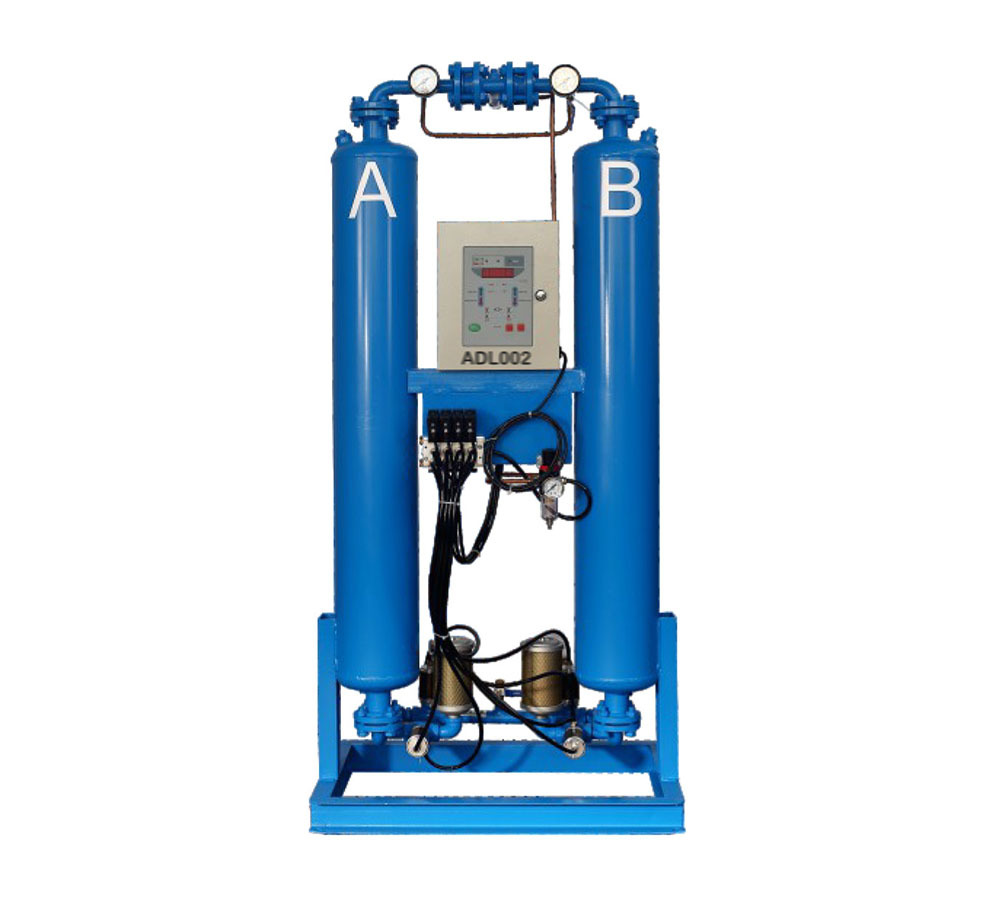

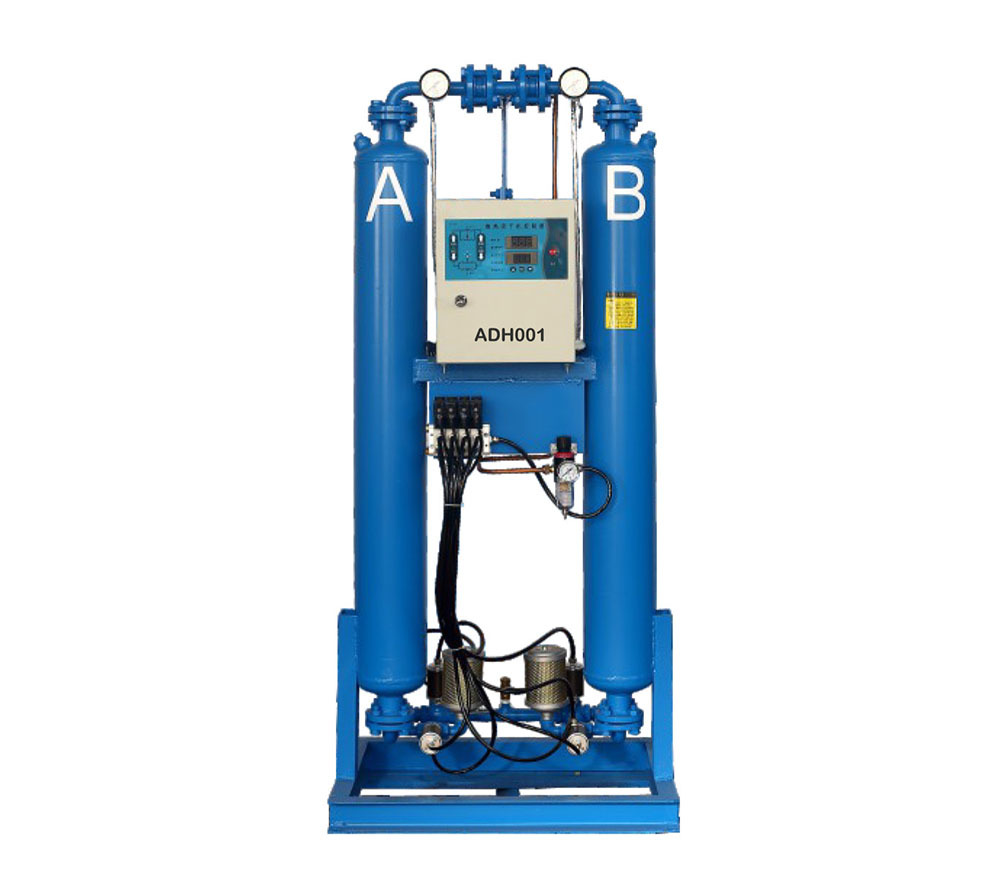

The opening and closing of the two air intake valves and two exhaust valves of the dryer are controlled by the solenoid valve.

Product features:

1. Sliding column structure, good sealing, sensitive response;

2. Three-position solenoid valve has three central functions to choose from;

3. The double-headed two-position solenoid valve has a memory function;

4. The inner hole is processed with special technology, the friction resistance is small, the starting air pressure is low, and the service life is long;

5. No oil lubrication is required;

6. It can be integrated with the base valve group to save installation space;

7. An auxiliary manual device facilitates installation and debugging;

Installation and use:

1. Before use, check whether the components are damaged during transportation, and then install and use;

2. During installation, please pay attention to the gas flow direction and whether the pipe thread type is correct. The working medium must be filtered through a 40um filter;

3. Please pay attention to whether the installation conditions meet the technical requirements (such as "voltage", "operating frequency", "working pressure", "operating temperature range", etc.), and then install and use;

4. Pay attention to the gas flow direction during installation. P is the air inlet, A(B) is the working port, and R(S) is the exhaust port;

5. Avoid using in a vibrating environment as much as possible, and pay attention to antifreeze measures at low temperatures;

6. When connecting the pipeline, pay attention to not exceeding the end face of the joint thread when winding the sealing tape, and clean the dust, iron filings, and other dirt in the pipeline joint to prevent impurities or foreign objects from entering the valve body;

7. Please pay attention to dust prevention, and it is recommended to install a silencer or silencer throttle valve at the exhaust port. When not in use, dust caps should be installed at the inlet and outlet;

8. When debugging the whole machine, it is recommended to first debug with the manual device and then debug with power.