Applicable Environment

-

Tools and instruments

Tools and instruments -

Control system

Control system -

Spraying tools

Spraying tools -

Successful injection

Successful injection -

Auto shop

Auto shop -

Tire pressure

Tire pressure

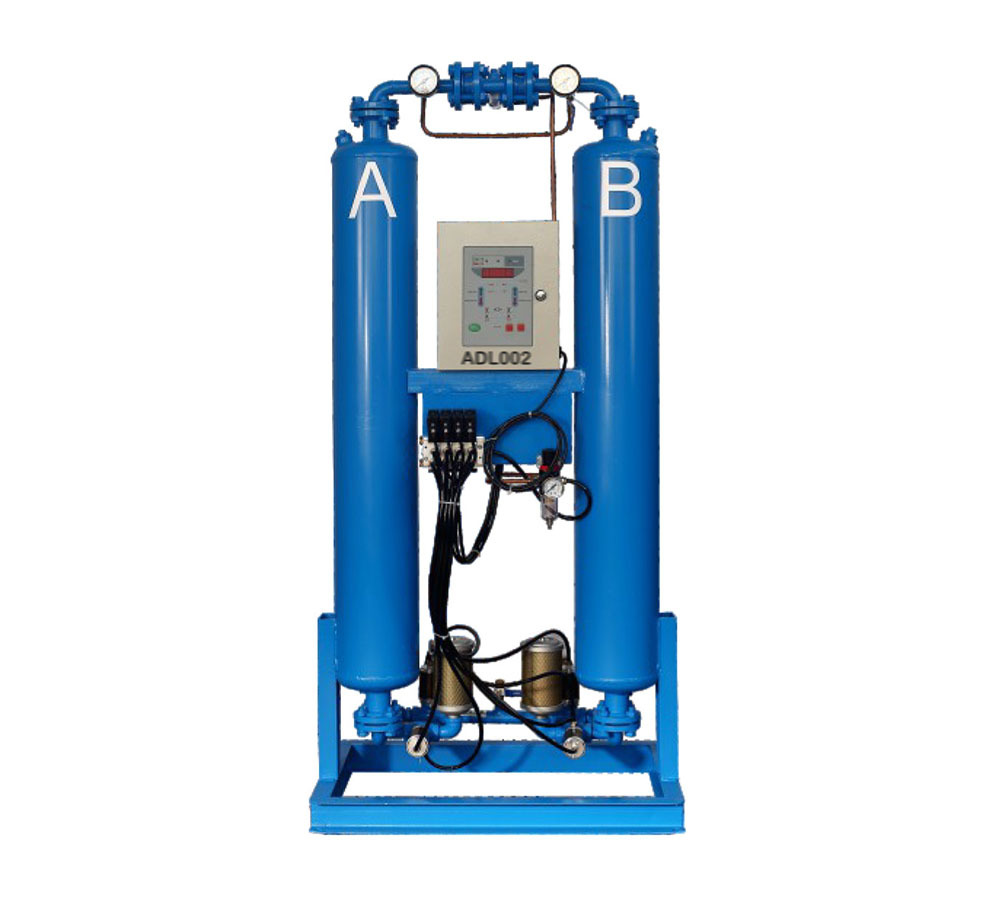

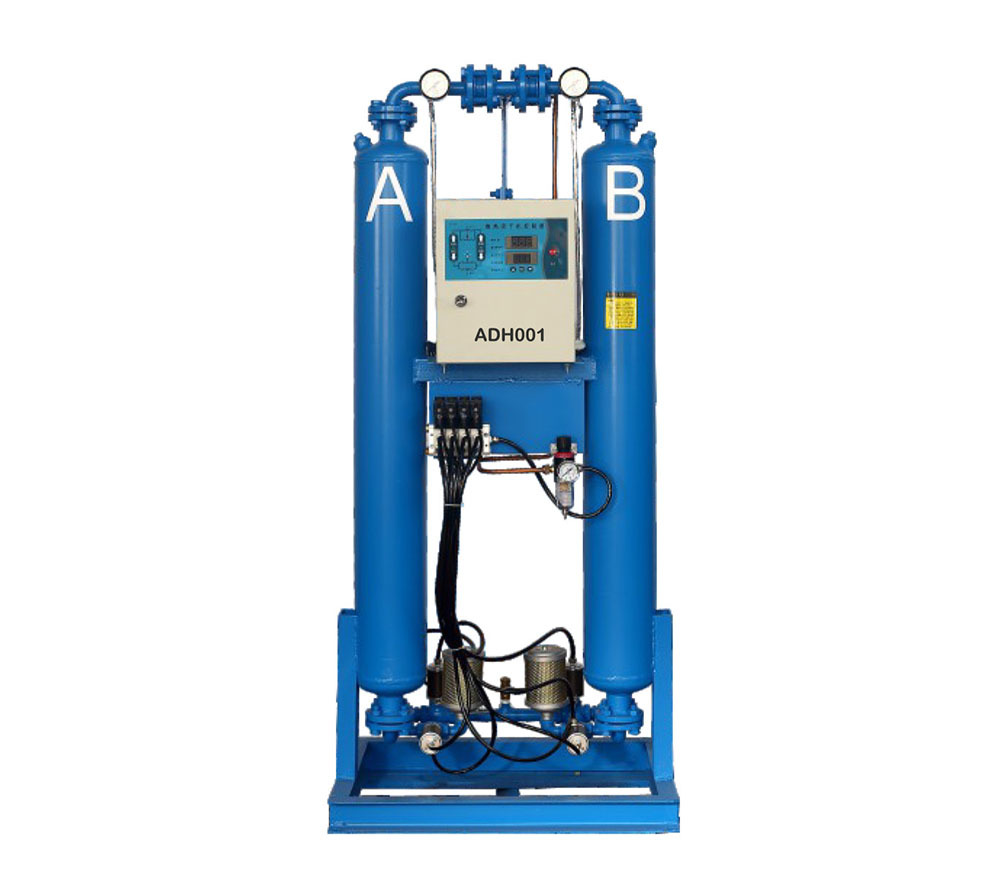

Product introduction

Working principle: Integrating the advantages of temperature swing adsorption and pressure swing adsorption, it adsorbs water vapor under normal temperature and high steam partial pressure (working pressure), and desorbs under high temperature and low steam partial pressure. The moisture adsorbed by the adsorbent during the adsorption process is thoroughly removed during the regeneration process through the combined action of thermal diffusion and low pressure of the regeneration gas.

If the regeneration gas is heated appropriately before use for adsorbent regeneration, the consumption of finished gas can be reduced. Therefore, a micro-heat regeneration adsorption dryer is produced, which has the advantages of small regeneration gas volume, good economy, and stable operation.

Workflow: Adsorption: Wet air enters the A drying cylinder from the lower diameter through the solenoid valve, flows upward through the adsorbent layer, and the dried compressed air is discharged from the upper diameter; Regeneration: Part of the dry compressed air (about 7%) passes through the regeneration gas regulating valve at the upper diameter and enters the heater for heating. This hot air enters the B drying cylinder and desorbs and regenerates the adsorbent in the B drying cylinder from top to bottom, restoring the adsorption capacity of the adsorbent. The regeneration gas is discharged to the atmosphere through the lower diameter valve and silencer; Pressure equalization: After the adsorbent regeneration is completed, the switching valve is closed, and the B drying cylinder is pressurized to the online working pressure for preparation to switch; Switching: The lower diameter valve opens, and the A and B drying cylinders complete the switching, with the B cylinder entering adsorption and the A cylinder undergoing pressure relief regeneration. The working sequence, working time, and heating temperature are automatically controlled by the controller.

Operating Requirements: Inlet temperature 0~45℃, ambient temperature -20~40℃, inlet oil content ≤0.5ppm, pneumatic valve air pressure ≥0.4MPa.

Selection: Micro-heat regeneration adsorption dryers are small, lightweight, easy to maintain, and have a gas consumption of ≤7%, with an atmospheric pressure dew point of -50~-30℃. However, the processing flow rate is small, so it is suitable for occasions with a small air volume but high drying requirements.

Model Parameters

|

Model |

Air Processing Capacity m³/min |

Power Supply V/50Hz |

Air Pipe Diameter | Dimensions L X W X H mm |

Weight kg |

||

|

ADH001 |

1.8 |

1/220 |

G3/4 |

650*350*1500 |

100 |

||

|

ADH002 |

2.8 |

2/220 |

G3/4 |

700*460*1550 |

120 |

||

|

ADH003 |

3.8 |

2/220 |

G1 |

1000*480*1650 |

140 |

||

|

ADH004 |

5.5 |

3/220 |

G1 1/2 |

1000*650*1700 |

270 |

||

|

ADH006 |

6.8 |

3/220 |

G1 1/2 |

1000*650*1900 |

300 |

||

|

ADH008 |

8.8 |

4.5/220 |

G2 |

1100*700*1900 |

355 |

||

|

ADH010 |

11.5 |

4.5/220 |

G2 |

1100*700*2100 |

370 |

||

|

ADH012 |

14 |

6.5/380 |

G2 1/2 |

1200*850*2100 |

550 |

||

|

ADH015 |

16 |

6.5/380 |

G2 1/2 |

1200*850*2100 |

620 |

||

|

ADH020 |

22.8 |

10/380 |

DN80 |

1400*1000*2150 |

780 |

||

|

ADH025 |

28.5 |

10/380 |

DN80 |

1400*1000*2400 |

1250 |

||

|

ADH030 |

35 |

12/380 |

DN80 |

1600*1100*2450 |

1700 |

||

|

ADH040 |

45 |

15/380 |

DN100 |

1700*1100*2550 |

2000 |

||

|

ADH050 |

55 |

18/380 |

DN100 |

2100*1100*2700 |

2500 |

||

|

ADH060 |

65 |

20/380 |

DN125 |

2000*1200*2900 |

3000 |

||

|

ADH080 |

85 |

25/380 |

DN150 |

2200*1600*2950 |

3550 |

||

|

ADH100 |

105 |

30/380 |

DN150 |

2600*1600*2950 |

4500 |

||

|

ADH120 |

120 |

35/380 |

DN200 |

2800*1700*2850 |

5000 |

||

|

ADH160 |

160 |

40/380 |

DN200 |

3000*1900*3300 |

6500 |

||

|

ADH200 |

200 |

50/380 |

DN250 |

3500*2200*3300 |

8000 |

||

| ADH250 | 250 | 60/380 | DN250 | 3800*2400*3300 | 9000 | ||

| ADH300 | 300 | 70/380 | DN300 | 4200*2600*3300 | 10000 | ||

Note:

1. The throughput in the table is calculated based on standard operating conditions (inlet pressure 0.7Mpa, inlet temperature 38℃);

2. When the actual operating conditions are different from the standard operating conditions, the correction coefficient should be calculated according to the pressure correction formula.

Pressure correction formula: Pressure correction coefficient = Actual inlet pressure / Standard inlet pressure;

3. 304 and 316 materials are available for pre-order.

4. Working pressure within 4.5MPa is available for pre-order.

5. Pressure dew point -20~-70℃