Applicable Environment

-

Tools and instruments

Tools and instruments -

Control system

Control system -

Spraying tools

Spraying tools -

Successful injection

Successful injection -

Auto shop

Auto shop -

Tire pressure

Tire pressure

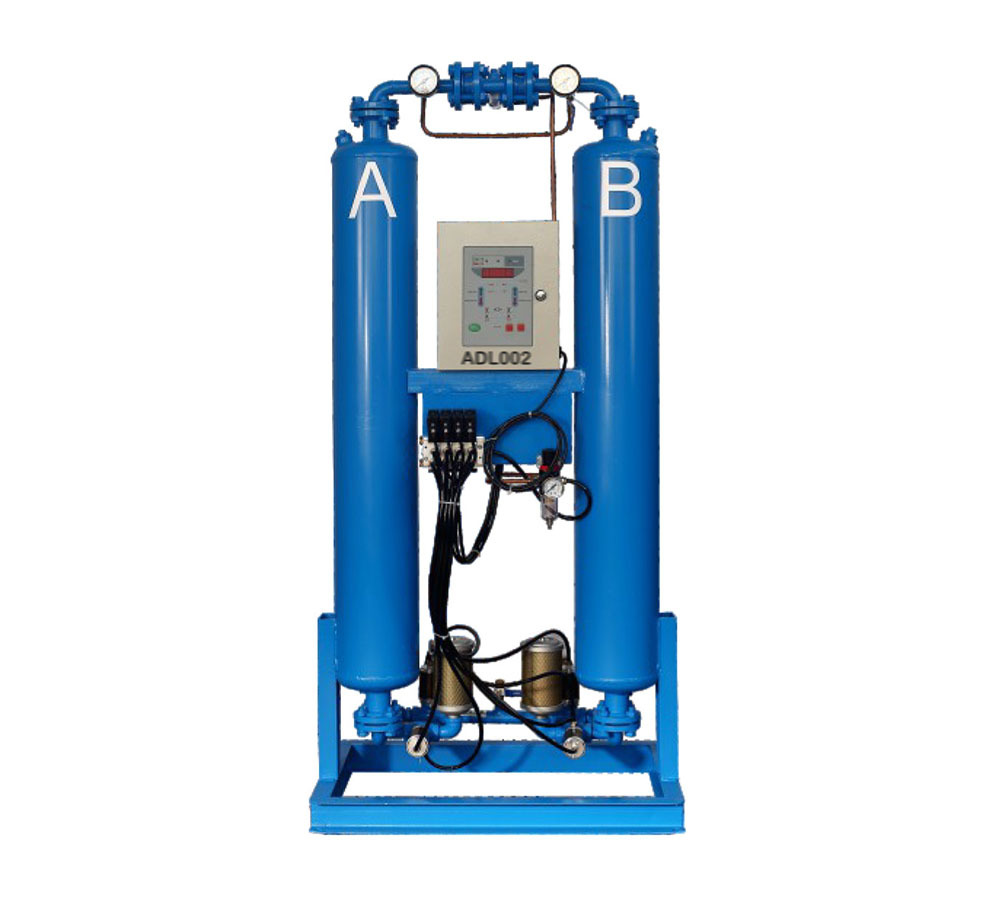

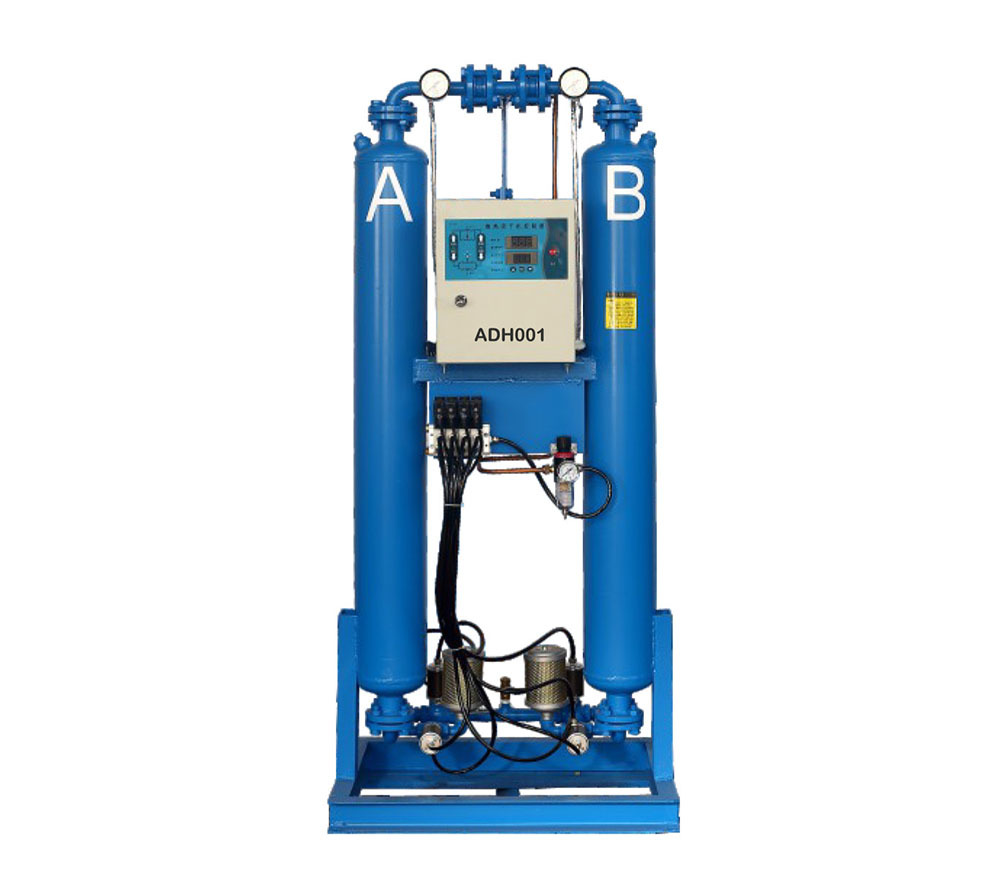

AD-M2/M4 series modular dryer

Technical parameters of non-thermal regeneration type

|

Operating ambient temperature |

0-50℃ |

|

Working medium temperature |

5-50C |

|

Working pressure |

0.45-0.85Mpa |

|

Due to force loss |

<0.015Mpa |

|

Regeneration gas consumption |

5%-8% (Customizable ultra-energy-saving type) |

|

Noise |

<65Db (Customizable ultra-quiet type) |

|

Power |

220V/50HZ/0.1KW (Customizable micro-heat type) |

|

Control method |

Integrated controller/PLC controller |

|

Dew point |

-40℃ (Customizable -70℃ type/Customizable dew point display type) |

|

Model |

Standard processing capacity (M3/minute) |

Interface diameter (inch) |

Dimensions (mm) |

Weight (kg) |

Matching theoretical air compressor power |

||

|

Pressure 0.7Mpa |

Length |

Width |

Height |

||||

|

AD-M2-3 |

7.5 |

2" |

660 |

330 |

1700 |

145 |

50HP-37.5KW |

|

AD-M2-4 |

10 |

2" |

890 |

330 |

1700 |

175 |

75HP-57KW |

|

AD-M2-6 |

15 |

2" |

1050 |

330 |

1700 |

250 |

100HP-75KW |

|

AD-M2-7 |

17.5 |

2" |

1190 |

330 |

1700 |

287 |

125HP-90KW |

|

AD-M2-8 |

20 |

3" |

1310 |

330 |

1700 |

325 |

150HP-110KW |

|

AD-M2-10 |

25 |

3" |

1570 |

330 |

1700 |

405 |

175HP-132KW |

|

AD-M4-6 |

30 |

3" |

1050 |

660 |

1700 |

510 |

175HP-132KW |

|

AD-M4-7 |

35 |

3" |

1190 |

660 |

1700 |

585 |

200HP-150KW |

|

AD-M4-8 |

40 |

4" |

1310 |

660 |

1700 |

675 |

250HP-185KW |

|

AD-M4-10 |

50 |

4" |

1570 |

660 |

1700 |

825 |

300-350HP-250KW |

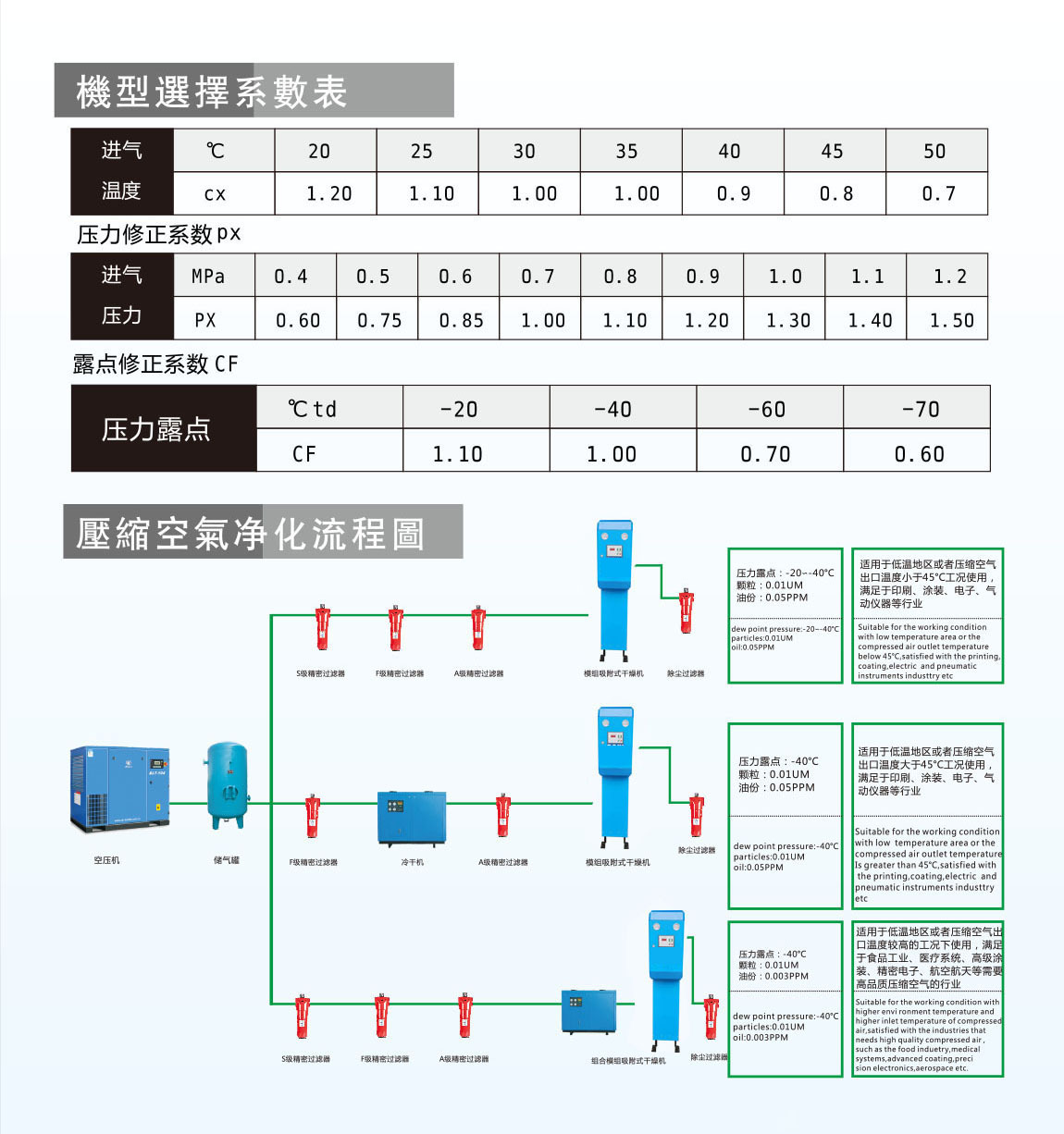

Model selection coefficient table

|

Inlet air |

℃ |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

|

Temperature |

cx |

1.20 |

1.10 |

1.00 |

1.00 |

0.9 |

0.8 |

0.7 |

Pressure correction coefficient PX

|

Inlet air |

MPa |

0.4 |

0.5 |

0.6 |

0.7 |

0.8 |

0.9 |

1.0 |

1.1 |

1.2 |

|

Pressure correction coefficient PX |

PX |

0.60 |

0.75 |

0.85 |

1.00 |

1.10 |

1.20 |

1.30 |

1.40 |

1.50 |

Dew point correction coefficient CF

|

Pressure dew point |

℃td |

-20 |

-40 |

-60 |

-70 |

|

CF |

1.10 |

1.00 |

0.70 |

0.60 |

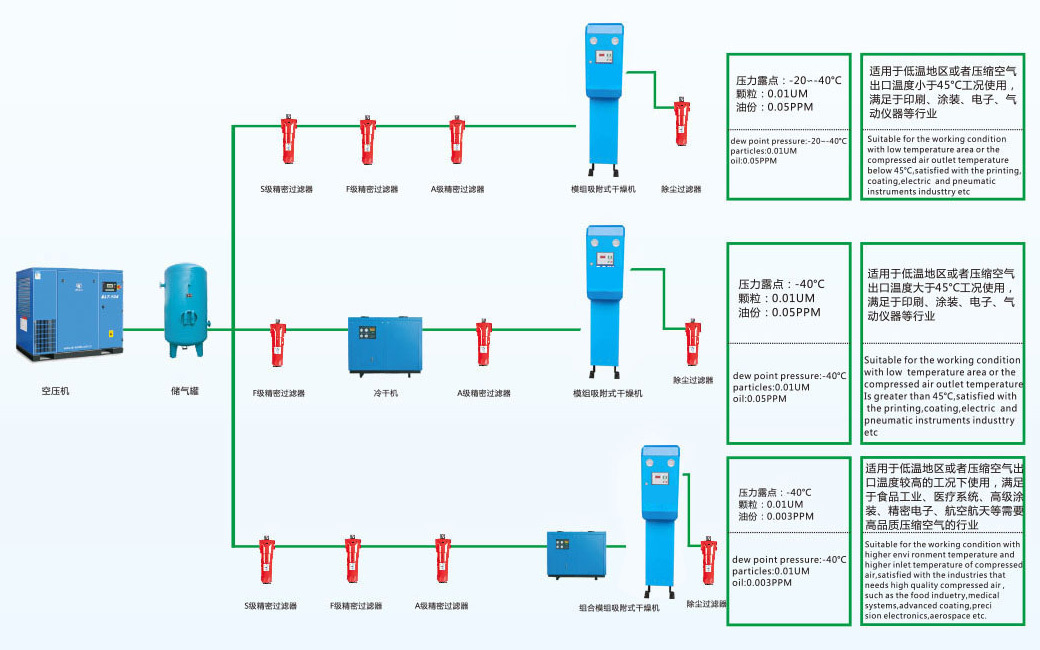

Compressed air purification process diagram

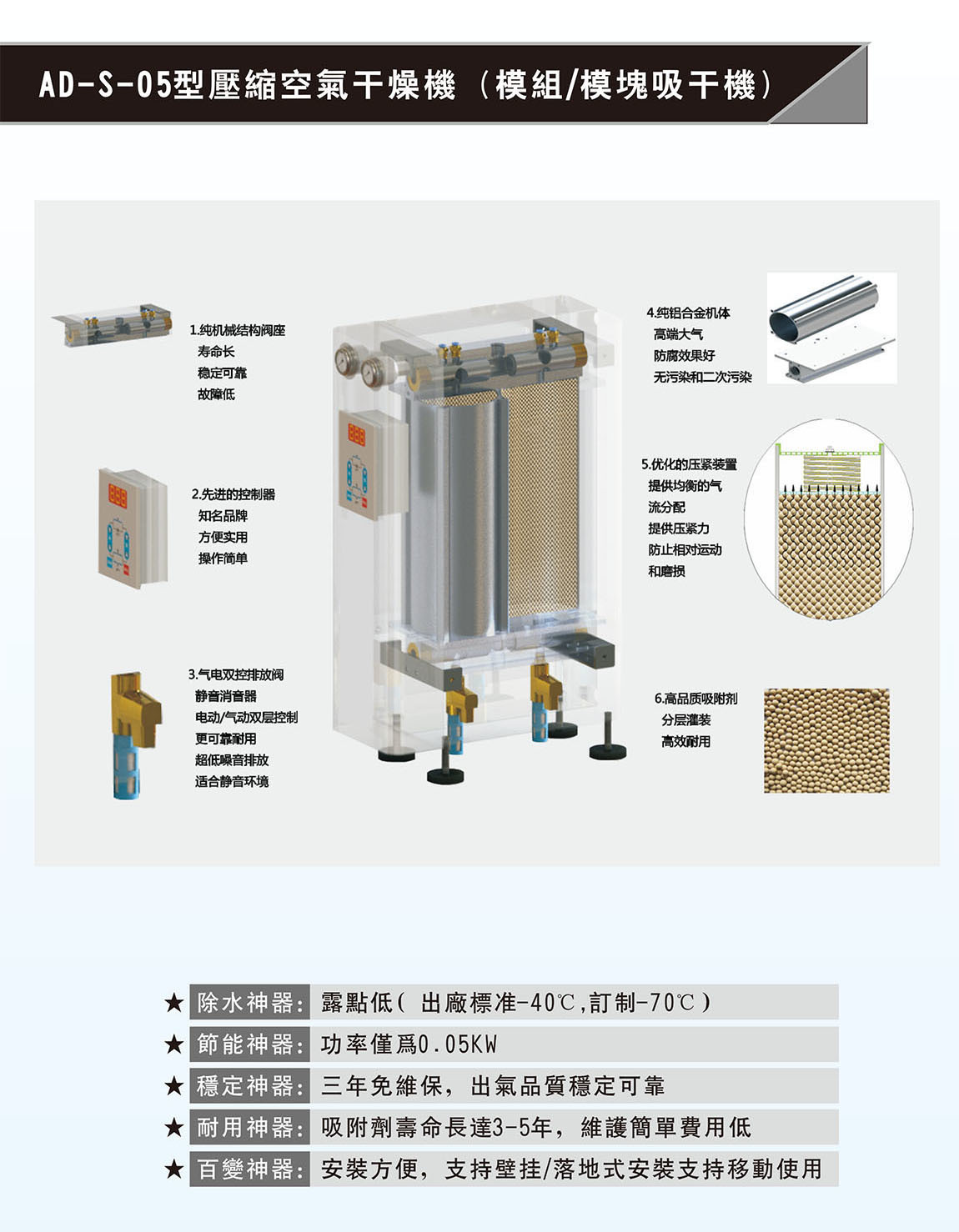

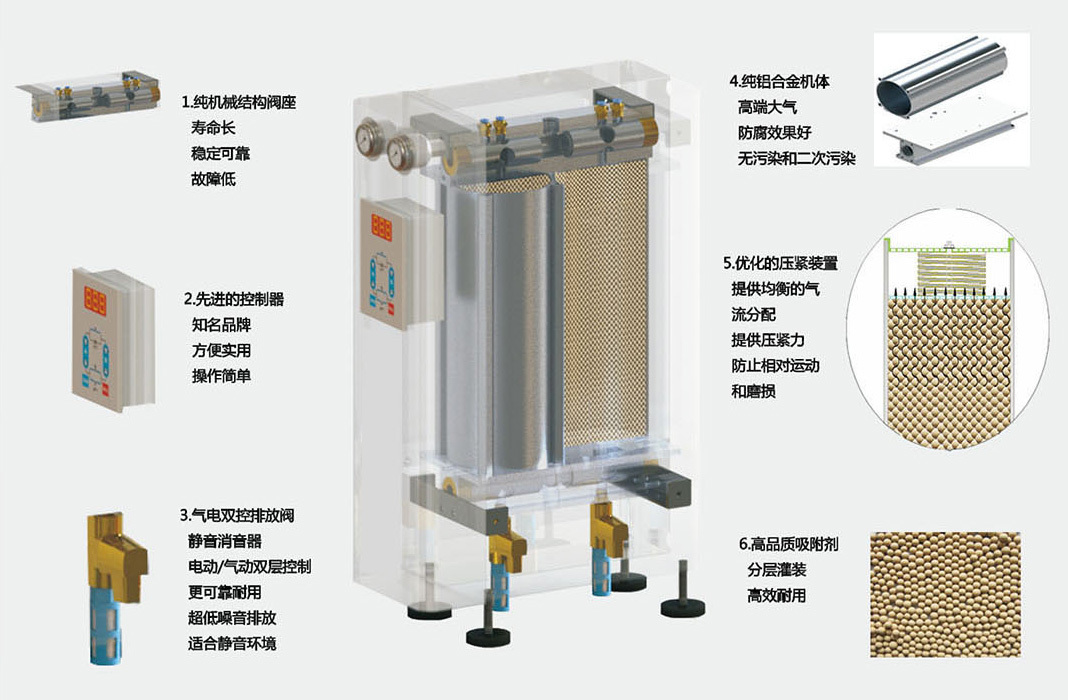

AD-S-05 compressed air dryer (modular/module dryer)

★Water removal artifact: Low dew point (factory standard -40℃, customized -70℃)

★Energy-saving artifact: Power is only 0.05KW

★Stable artifact: Three-year free maintenance, stable and reliable factory quality

★Durable artifact: Adsorbent life up to 3-5 years, simple maintenance and low cost

★Versatile artifact: Easy installation, supports wall-mounted/floor-standing installation and mobile use

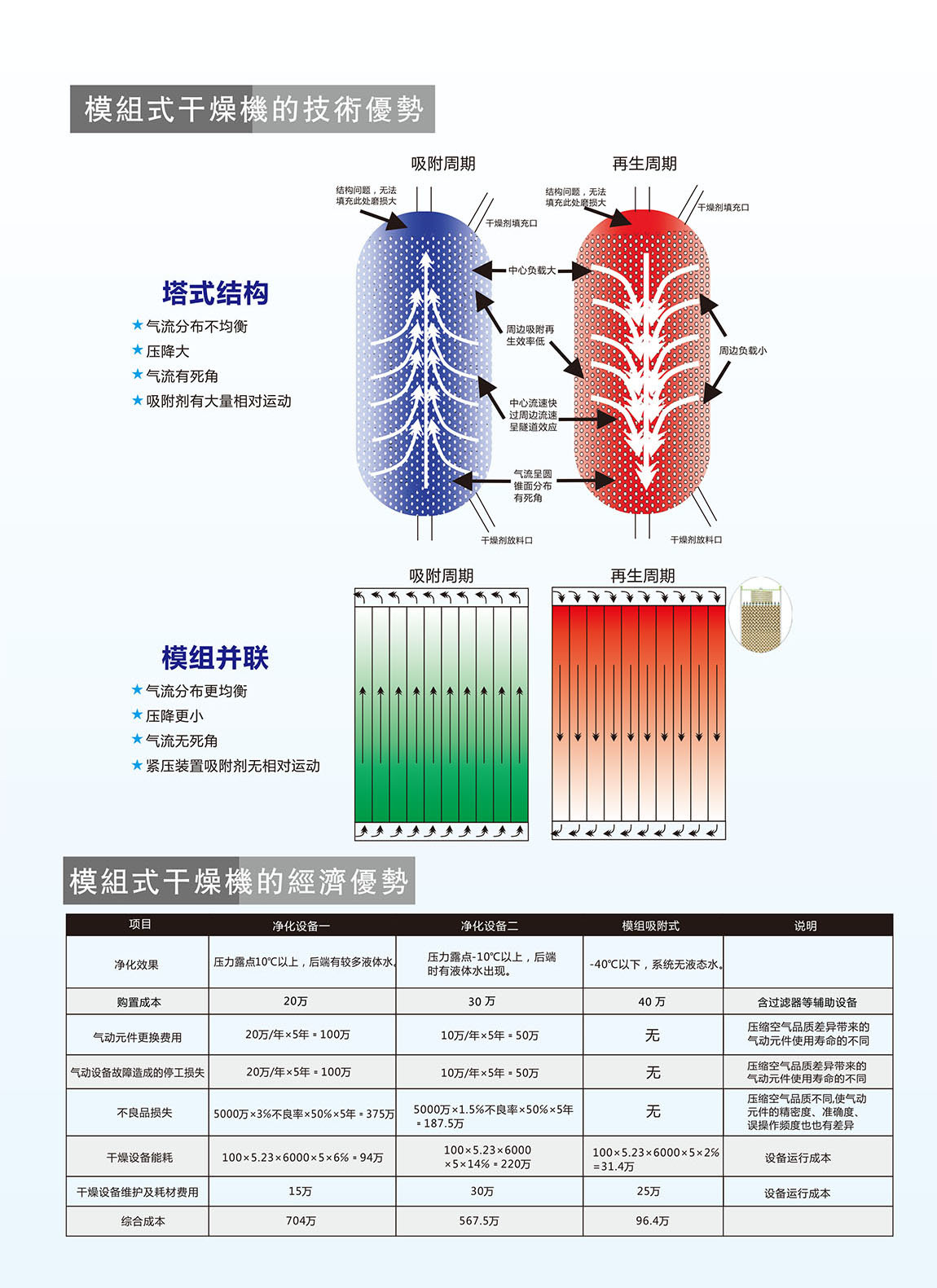

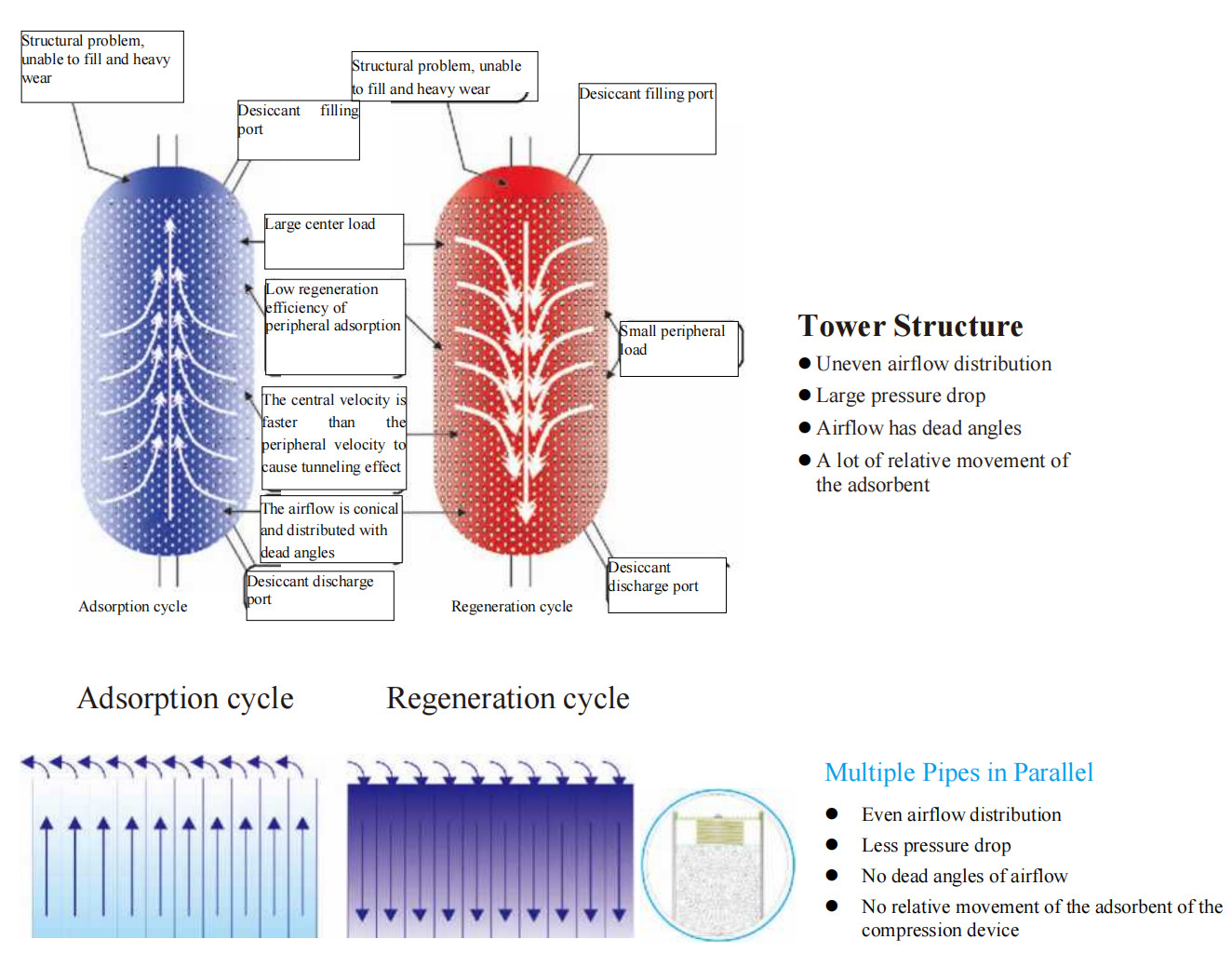

Technical advantages of modular dryers

Economic advantages of modular dryers

|

Project |

Purification equipment 1 |

Purification equipment 2 |

Modular adsorption type |

Description |

|

Purification effect |

Pressure dew point above 10℃, a lot of liquid water at the back end |

Pressure dew point above -10℃, a lot of liquid water at the back end |

Below -40℃, no liquid water in the system |

|

|

Purchase cost |

200,000 |

300,000 |

400,000 |

Including filters and other auxiliary equipment |

|

Pneumatic component replacement costs |

200,000/year × 5 years = 1,000,000 |

100,000/year × 5 years = 500,000 |

None |

Differences in compressed air quality lead to differences in the service life of pneumatic components |

|

Production downtime losses caused by gas equipment failures |

200,000/year × 5 years = 1,000,000 |

100,000/year × 5 years = 500,000 |

None |

Differences in compressed air quality lead to differences in the service life of pneumatic components |

|

Defective product losses |

50,000,000 × 3% defect rate × 50% × 5 years = 3,750,000 |

50,000,000 × 1.5% defect rate × 50% × 5 years = 1,875,000 |

None |

Different compressed air quality results in differences in the precision, accuracy, and frequency of misoperation of pneumatic components |

|

Energy consumption of drying equipment |

100 × 5.23 × 6000 × 5 × 6% = 940,000 |

100 × 5.23 × 6000 × 5 × 14% = 2,200,000 |

100 × 5.23 × 6000 × 5 × 2% = 314,000 |

Equipment operating costs |

|

Maintenance and consumable costs for drying equipment |

150,000 |

300,000 |

250,000 |

Equipment operating costs |

|

Total cost |

7,040,000 |

5,675,000 |

964,000 |

|