Applicable environment

-

Tools and instruments

Tools and instruments -

Control system

Control system -

Spraying tools

Spraying tools -

Successful injection

Successful injection -

Auto shop

Auto shop -

Tire pressure

Tire pressure

Product introduction

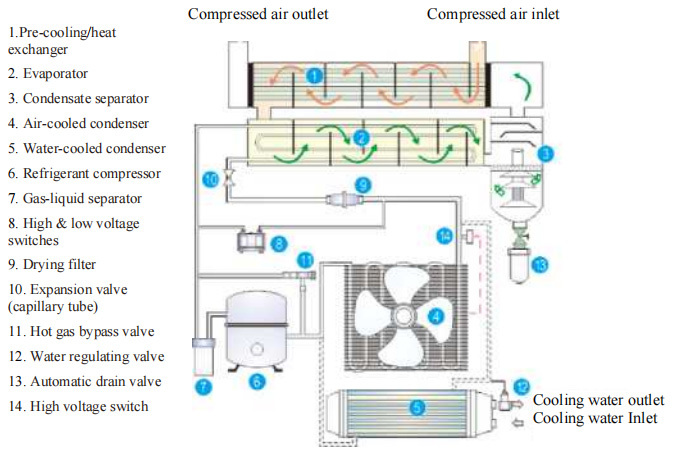

Working principle: Based on the principle of air freezing and drying (cooling and condensation), refrigeration equipment is used to cool humid and hot compressed air to a certain dew point temperature (saturation temperature), and then the corresponding water content is precipitated. The gas-liquid separation is carried out through a gas-water separator, and the separated liquid water is discharged through an automatic drain, so that the compressed air obtains the required dry dew point.

Basic structure: It consists of three major parts: refrigeration system, heat exchanger system and electrical control system.

The refrigeration system mainly consists of five major components: refrigeration compressor, evaporator, condenser, thermostatic expansion valve, and hot gas bypass valve. The refrigerant continuously circulates and flows in the refrigeration system, undergoes phase changes, and performs multiple heat exchanges to complete the cooling of the compressed air.

The heat exchange system mainly consists of a heat exchanger (also known as a pre-cooler or regenerator), evaporator tubes, and a cyclone separator. It completes the heat recovery, provides cooling space and gas-liquid separation.

The electrical control system mainly consists of contactors, thermal relays, and time relays. The electrical control system is used to complete a series of control and protection actions for the entire refrigeration system.

Workflow:

Compressed air flow The compressed air to be dried, entering the refrigerated dryer, first enters the pre-cooler, where it exchanges heat with the dry low-temperature cold air from the evaporator, and its enthalpy, temperature and moisture content decrease. The pressure dew point of the compressed air leaving the pre-cooler has been reduced, but it has not yet reached the drying requirement. The air to be dried continues to enter the evaporator. In the evaporator, it exchanges heat with the refrigerant, and the temperature continues to decrease. At the evaporator outlet, its temperature reaches the required pressure dew point. The gas-water mixture from the evaporator enters the gas-liquid separator, where the precipitated water is separated, and the dry air then enters the pre-cooler and exchanges heat with the hot air entering the refrigerated dryer, so that its temperature rises before being discharged from the refrigerated dryer.

Refrigerant flow The high-temperature and high-pressure refrigerant gas discharged from the refrigeration compressor enters the condenser, releases heat, and condenses into a liquid. The liquid refrigerant from the condenser passes through a throttling device (capillary tube or expansion valve) to reduce pressure and temperature, and becomes a low-temperature gas-liquid two-phase state entering the evaporator, where it exchanges heat with the air to be dried and vaporizes. After the superheated gas leaves the evaporator, it enters the refrigeration compressor for the next cycle. The evaporator heat exchange surface temperature of the refrigerated dryer is below 0℃, and frost and ice will form on the heat exchange surface, affecting the flow of the air to be dried, and thus affecting the operation of the entire refrigerated dryer. Therefore, it is necessary to ensure that the evaporator heat exchange surface temperature is above 0℃, which requires controlling the refrigerant evaporation temperature not to be too low. For this purpose, a hot gas bypass valve is set in the compressor discharge pipe and the outlet pipe from the expansion valve to the evaporator inlet to adjust the evaporation pressure. When the evaporation pressure is reduced to a certain extent, the hot gas bypass valve is turned on, and high-temperature and high-pressure gas directly enters the evaporator to maintain the temperature of the evaporator heat exchange surface above 0℃.

Operating requirements: Inlet temperature <80℃, ambient temperature 5~45℃, operating pressure 0.7~1.0MPa (pressure within 4.5MPa can be pre-ordered)

Technical features: The compressed air heat exchange process of Yingke refrigerated air dryer (hereinafter referred to as air dryer) is that the incoming humid hot compressed air first exchanges heat with the dried cold compressed air in the heat exchanger, and the preliminarily cooled compressed air exchanges heat with the low-temperature and low-pressure refrigerant in the evaporator. This design greatly improves the heat exchange amount, obtaining good dryness and reducing the load of the refrigeration compressor, condenser and fan, thus achieving energy saving and efficiency. Through this design process, the outlet temperature of Yingke air dryer (RD0080 and above specifications) can reach about 25℃ (the outlet temperature of many brands of air dryers on the market is around 10℃), which is closer to the ambient temperature and effectively reduces the generation of condensed water in the rear compressed air pipeline.

Performance characteristics:

1. The refrigeration compressor adopts brands such as Danfoss of the United States, Panasonic and Daikin of Japan. It has a compact structure, low noise, large refrigeration power, extremely high reliability, and is a highly efficient and energy-saving core. The refrigeration compressor has an overload protection function to ensure safer operation of the refrigeration compressor and ensure the reliability of the system.

2. The refrigeration system uses Danfoss thermostatic expansion valves and thermal bypass valves (RD0200 and above specifications) to reliably and effectively adjust the refrigerant supply according to the load of the dryer, achieving energy saving.

3. The heat exchanger uses a combined structure of volumetric and tube-in-tube types to prevent scaling, reduce the load on the refrigeration system, and ensure the long-term reliable operation of the entire machine.

4. The heat exchange rate can reach 90%, 30% higher than similar products, and energy saving is about 10~20%.

5. The heat exchanger uses copper tubes with a thickness of 1mm, and the evaporator uses copper tubes with a thickness of 0.5mm, which is thicker than similar products, greatly reducing the risk of leakage in the refrigeration system.

6. The high-efficiency cyclone blade baffle water separator can separate 99% of liquid water, achieving thorough gas-liquid separation, avoiding secondary evaporation of water, and ensuring the drying effect of the dryer.

7. Schneider Electric products are used for electrical control to ensure accurate and reliable operation of the dryer.

8. Advanced domestic electronic automatic drainers are selected to reliably drain the condensate outside the machine without causing airflow loss.

9. The compact and scientific structural design results in a small size, occupying less space than similar dryers.

10. The scientific machine design completely prevents "ice blockage" and effectively prevents condensation in the outlet pipe.

11. Fully complies with ISO8573.1 international standards.

Selection: Refrigerated dryers are suitable for occasions with high humidity, large air handling capacity, and pressure dew point temperature of 2~10℃. They have advantages such as low energy consumption, compact structure, small footprint, low noise, easy maintenance, and low maintenance costs.

The corrected processed air must not exceed the rated processed air volume given by the refrigerated dryer product. Select the dryer specifications accordingly. The corrected processed air volume is determined by the following formula:

q=qc/(C1*C2) [L/min(standard state)]

Where qc---actual processed air volume of the dryer, L/min (standard state)

C1---temperature correction coefficient (standard condition inlet air temperature/actual inlet air temperature)

C2---inlet air pressure correction coefficient (actual inlet air pressure/standard condition inlet air pressure)

Water-cooled model parameters

|

Model |

Air Processing m³/min |

Compressor |

Cooling water volume m³/min |

Power |

Air Pipe Diameter | Dimensions L X W X H mm |

Weight kg |

|

RD0120W |

14 |

3 |

2.8 |

380 |

G2 1/2" |

700*1000*1000 |

160 |

|

RD0150W |

16 |

4 |

3 |

380 |

G2 1/2" |

800*1000*1000 |

165 |

|

RD0200W |

22.8 |

5 |

3.5 |

380 |

DN80 |

700*1450*1200 |

250 |

|

RD0250W |

28.5 |

6 |

4 |

380 |

DN80 |

800*1450*1200 |

300 |

|

RD0300W |

35 |

8 |

5 |

380 |

DN80 |

1800*1000*1450 |

400 |

|

RD0400W |

45 |

10 |

7 |

380 |

DN100 |

2000*1000*1480 |

500 |

|

RD0500W |

55 |

12.5 |

9 |

380 |

DN100 |

2200*1100*1580 |

600 |

|

RD0600W |

65 |

15 |

10 |

380 |

DN125 |

2200*1100*1580 |

700 |

|

RD0800W |

85 |

20 |

12 |

380 |

DN150 |

2300*1300*1720 |

900 |

|

RD1000W |

105 |

25 |

14 |

380 |

DN150 |

2500*1400*2100 |

1100 |

|

RD1200W |

120 |

30 |

16 |

380 |

DN200 |

2600*1800*2100 |

1500 |

|

RD1600W |

160 |

40 |

18 |

380 |

DN200 |

3300*2000*2100 |

1650 |

|

RD2000W |

200 |

50 |

24 |

380 |

DN250 |

3200*2000*2300 |

2000 |

|

RD2500W |

250 |

60 |

24 |

380 |

DN250 |

3800*2100*2400 |

2600 |

|

RD3000W |

300 |

70 |

35 |

380 |

DN300 |

4000*2100*2700 |

3500 |

|

RD3600W |

360 |

80 |

40 |

380 |

DN300 |

4200*2100*2700 |

4500 |

| RD4000W | 400 | 100 | 50 | 380 | DN300 | 4800*2600*2700 | 5000 |

| RD4500W | 450 | 125 | 55 | 380 | DN400 | 5000*2600*3000 | 5500 |

| RD5000W | 500 | 150 | 60 | 380 | DN400 | 5000*2800*3000 | 6000 |

Note:

1. The processing capacity in the table is calculated based on standard conditions (inlet temperature 38℃, inlet pressure 0.7MPa, ambient temperature 35℃);

2. When the actual conditions are different from the standard conditions, the correction coefficient should be calculated according to the temperature correction formula and the pressure correction formula.

Temperature correction formula: Temperature correction coefficient = standard condition inlet air temperature/actual inlet air temperature,

Pressure correction formula: Pressure correction coefficient = actual inlet air pressure/standard condition inlet air pressure;

3. Maximum inlet temperature 80℃, operating ambient temperature 5-45℃, pressure dew point 2~10℃;

4. The refrigeration compressor of the dryer defaults to using R22 refrigerant. If an environmentally friendly refrigeration compressor is required, the model of the environmentally friendly refrigerant should be specified in the order.

5. 304 and 316 materials are available for pre-order.

6. Working pressure within 4.5MPa is available for pre-order.