Applicable environment

-

Tools and instruments

Tools and instruments -

Control system

Control system -

Spraying tools

Spraying tools -

Injection successful

Injection successful -

Car shop

Car shop -

Tire pressure

Tire pressure

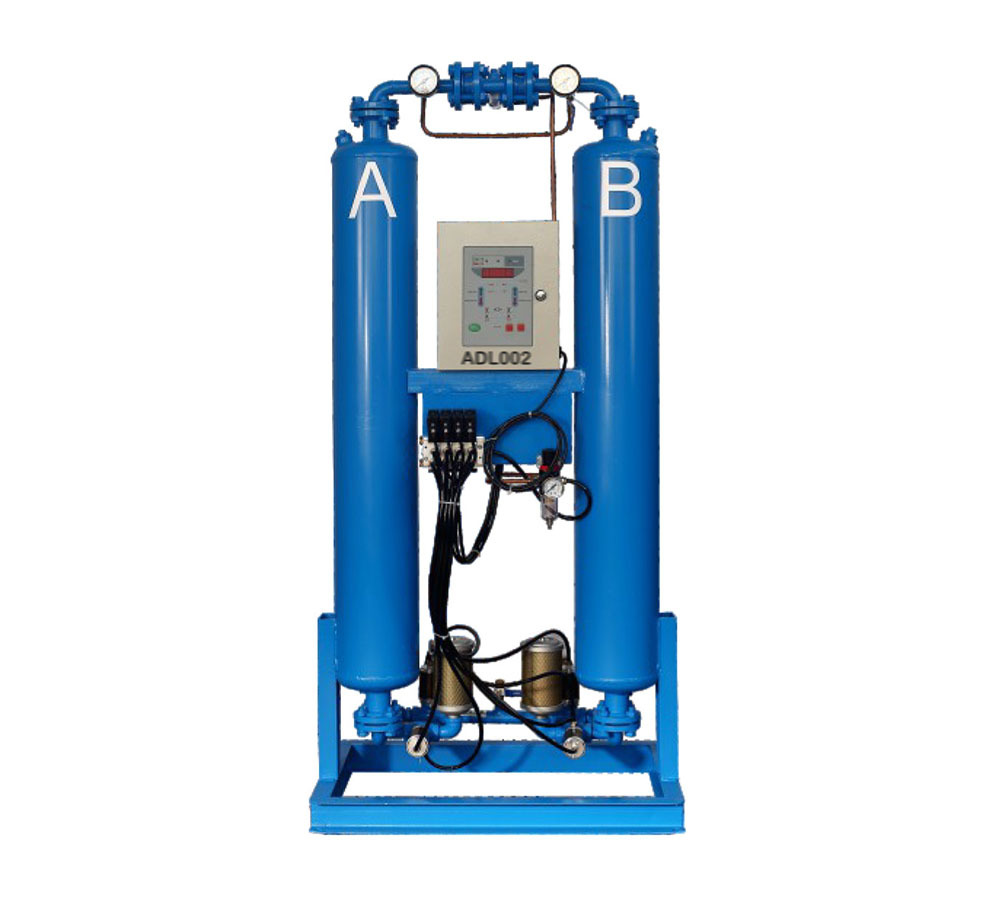

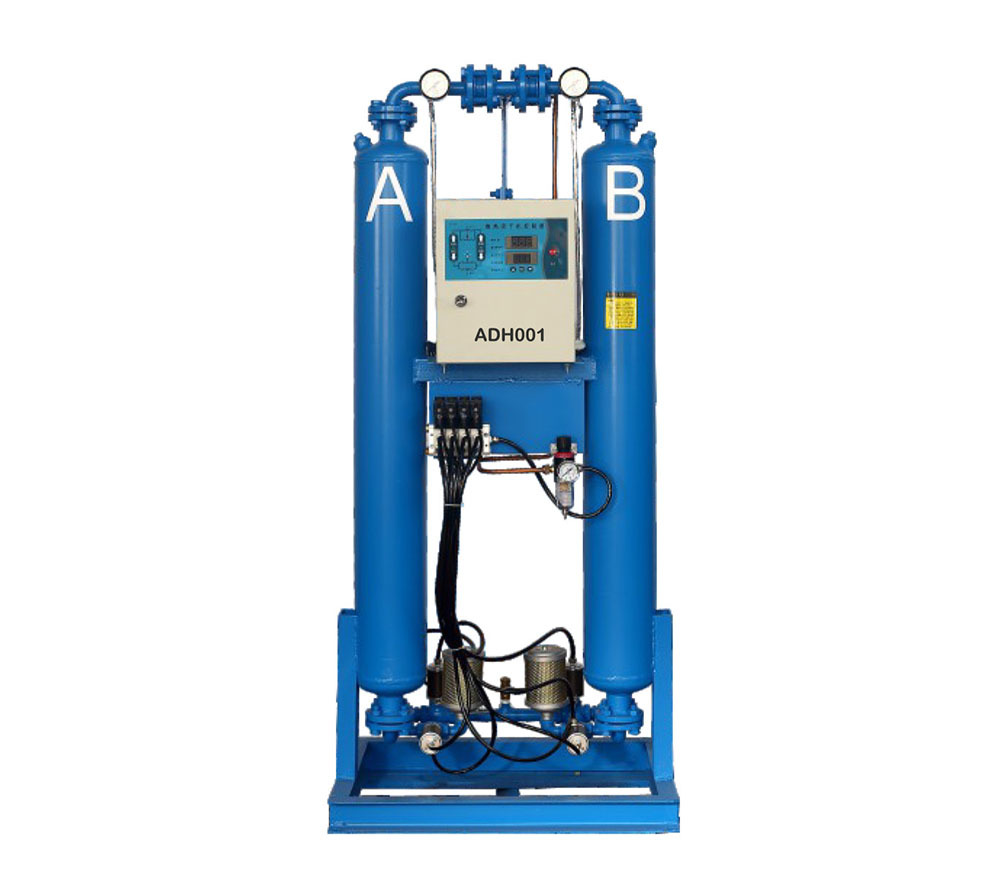

Product introduction

Pressure switches (also called pressure controllers) are used in refrigeration and air conditioning systems to avoid excessively low suction pressure and excessively high discharge pressure. Controllers can be used to start and stop refrigeration compressors and fans with air-cooled condensers.

Working principle:

The discharge pressure of the compressor drives the diaphragm to generate displacement, pushing the controller contacts to close and open. When the discharge pressure is low, the diaphragm moves, causing the circuit to open, the condensing fan stops working, and the condensing pressure rises; when the discharge pressure rises to a certain value, the circuit is connected, and the fan starts. Although the condensing pressure fluctuates under this control method, it can basically ensure that the condensing pressure is not too low when the ambient temperature is low.

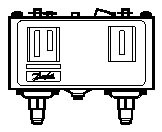

Large-scale refrigeration dryers use high and low pressure switches, namely double pressure controllers, which have two versions: both the left and right sides can be adjusted for high pressure, or the left side for low pressure adjustment and the right side for high pressure adjustment (LP signal version or LP+HP signal version). Enclosure protection level: IP30 or IP44

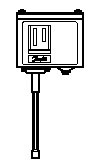

Small refrigeration dryers use high-pressure pressure controllers.

|

|

|

| High and low pressure switch |

High pressure switch |

Pressure switches (also called pressure controllers) can be used to start and stop refrigeration compressors and fans with air-cooled condensers.