Applicable Environment

-

Tools and Instruments

Tools and Instruments -

Control System

Control System -

Spraying Tools

Spraying Tools -

Successful Injection

Successful Injection -

Car Shop

Car Shop -

Tire Pressure

Tire Pressure

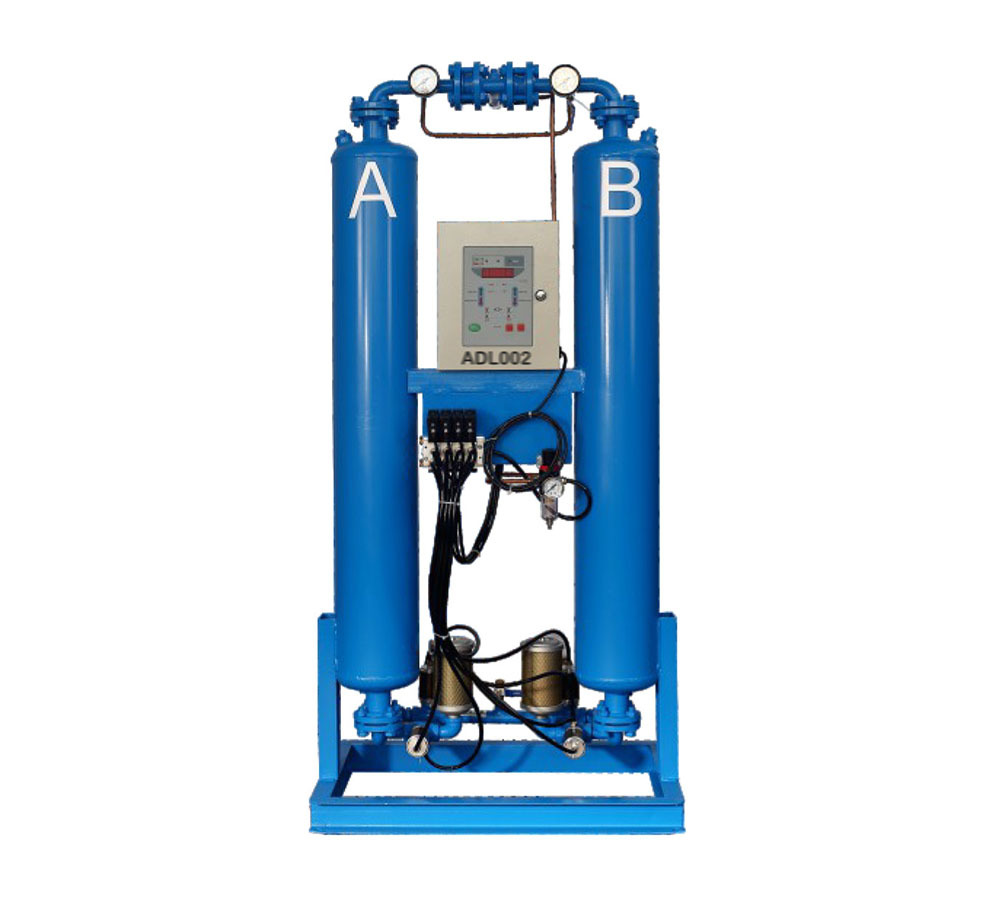

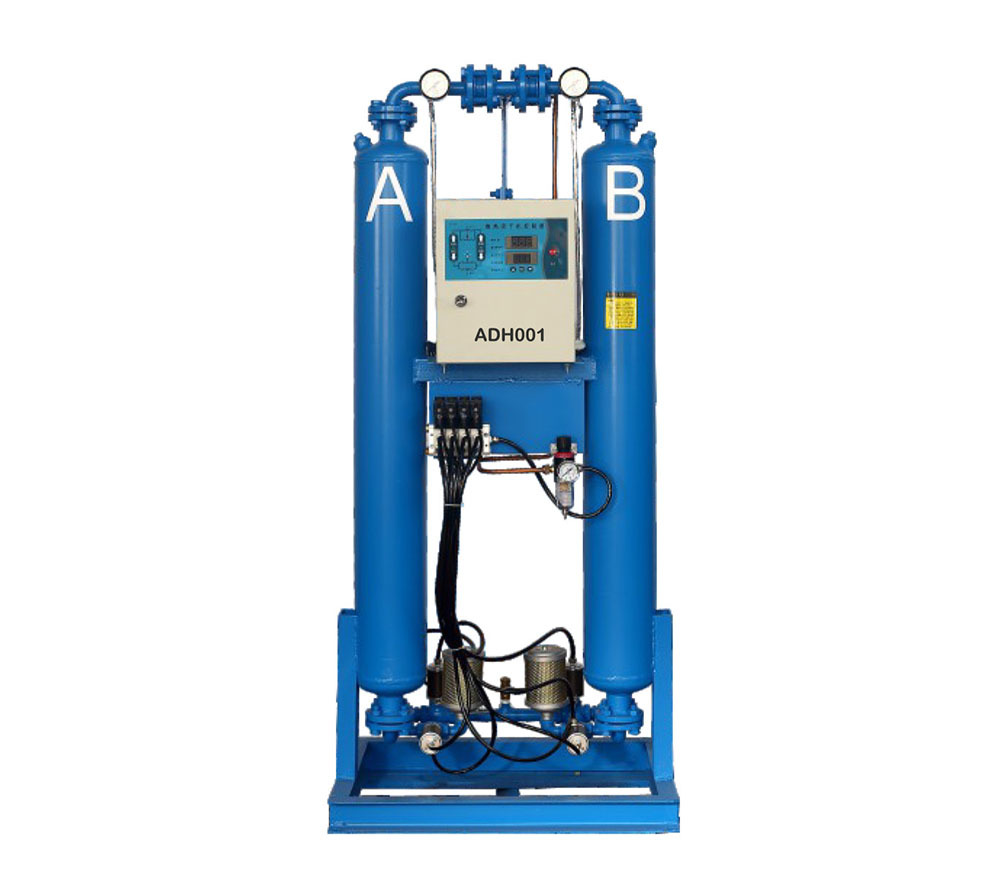

Product Introduction

Performance characteristics:

Unlike traditional mechanical automatic drainers, the float-type automatic drainer is a continuous dripping type. The housing is made of cast aluminum alloy, with a sprayed plastic coating on the surface. The inner and outer walls are corrosion-resistant, and the inside contains a stainless steel float drainage system. This product is reliable in operation, noise-free, requires no power, has no compressed air loss, and is not easily blocked, making it the best choice for compressed air drain valves.

Working principle:

The automatic drainer uses a die-cast aluminum shell assembly and contains a float drainage system. When the drainage buoyancy is less than the weight of the drainage float and the pressure exerted by the compressed air, the drain port is closed; when the buoyancy rises, the drainage float rises, and the drain port opens; when the condensate decreases, the drain port closes again, and this cycle repeats.

Application range:

It is widely used for gas-liquid discharge of low-flow compressed air filters. It is generally recommended to use with precision filters with a handling capacity of 10Nm³/min or less. For compressed air filters with larger handling capacity and more impurities, it is recommended to use the electronic drain valve MIC-A or MIC-B. The discharged oil-water mixture should be treated with our FYB series box-type waste oil collector or FYP series tank-type waste oil collector before being discharged into the environment.

Technical Parameters

| Condensate Inlet/Outlet |

1/2" |

| Maximum Working Pressure |

20Bar |

| Maximum Operating Temperature |

100oC |

| Maximum Discharge Capacity |

500 liters/hour |

Installation Requirements:

★The actual operating pressure and temperature must not exceed the values indicated on the label.

★Before installing the JAD20 drainer, the dirt, copper scraps, and rust in the compressed air system should be removed first. It is recommended to drain the system under full pressure for 1 minute before installation.

★During installation, this automatic drainer must be installed below the equipment's drainage device; otherwise, the condensate will fill up and affect the drainage effect.

★The JAD20 drain port can be used as a "free outflow port" or a drain pipe can be installed.

Maintenance and Care:

Please regularly check the drain valve.

Operating method: Unscrew the manual drain knob to allow the water inside the drainer to drain completely, until the compressed air inside the equipment enters the inner cylinder of the ball for a few minutes, then close the knob. If the amount of water discharged exceeds 0.5 liters, it means the automatic drainer is clogged and must be thoroughly cleaned.

The automatic drainer must be disassembled and its internal components cleaned annually. When cleaning, soap water or detergent can be used. Do not use organic solvents to avoid damaging rubber parts.