Applicable environment

-

Tools and instruments

Tools and instruments -

Control system

Control system -

Spray painting tools

Spray painting tools -

Successful injection

Successful injection -

Auto repair shop

Auto repair shop -

Tire pressure

Tire pressure

Product introduction

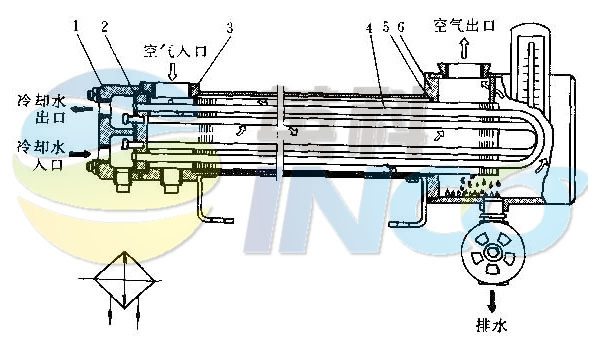

Function: The compressed air output by the air compressor can reach 120℃. At this temperature, the water in the air is completely gaseous. The function of the aftercooler is to cool the high-temperature air at the air compressor outlet to below 40℃, condensing a large amount of water vapor and deteriorated oil mist into liquid water droplets and oil droplets, so that they can be eliminated.

Working principle: The water-cooled aftercooler relies on forced input of cooling water along the reverse flow of hot air (hot air pipe) to reduce the temperature of the compressed air. The outlet air temperature of the water-cooled aftercooler is about 10℃ higher than the temperature of the cooling water. An automatic or manual drain should be installed at the lowest point of the aftercooler to drain condensed water, oil droplets and other impurities.

Product features: The heat dissipation area is 25 times that of the air-cooled type, the heat exchange is uniform, the water distribution efficiency is high, so it is suitable for occasions where the inlet air temperature is below 200℃, and the amount of air to be processed is large, the humidity is high, and there is a lot of dust.

Selection: Select the model of the aftercooler according to the system's operating pressure, the inlet air temperature of the aftercooler, the ambient temperature, the outlet air temperature of the aftercooler, and the amount of air to be processed. When the inlet air temperature exceeds 100℃ or the amount of air to be processed is very large, only a water-cooled aftercooler can be selected.

Model parameters

| Model |

Processing capacity |

Air pipe diameter |

Cooling water volume m³/h |

Cooling water pipe diameter |

Dimensions mm |

||

| Length (L) |

Width (W) |

Height (H) |

|||||

| DAC0120W |

14 |

G2 1/2" |

3 |

G1" |

800 |

430 |

1400 |

| DAC0200W |

22.8 |

DN80 |

5 |

G1 1/2" |

800 |

430 |

2000 |

| DAC0250W |

28.5 |

DN80 |

6 |

G1 1/2" |

1650 |

330 |

400 |

| DAC0300W |

35 |

DN80 |

8 |

G2" |

1650 |

400 |

500 |

| DAC0400W |

45 |

DN100 |

12 |

G2" |

2150 |

400 |

500 |

| DAC0500W |

55 |

DN100 |

14 |

G2 1/2" |

2150 |

450 |

560 |

| DAC0600W |

65 |

DN125 |

17 |

G2 1/2" |

2200 |

450 |

560 |

| DAC0800W |

85 |

DN150 |

21 |

G3" |

2200 |

500 |

600 |

| DAC1000W |

105 |

DN150 |

27 |

G3" |

2200 |

500 |

600 |