Applicable environment

-

Tools and instruments

Tools and instruments -

Control system

Control system -

Spraying tools

Spraying tools -

Injection successful

Injection successful -

Auto repair shop

Auto repair shop -

Tire pressure

Tire pressure

Product introduction

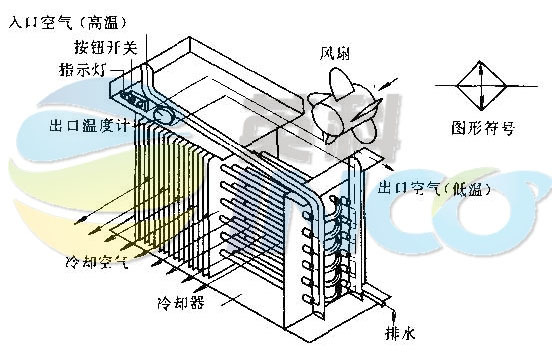

Function: The compressed air output by the air compressor can reach 120℃. At this temperature, the moisture in the air is completely gaseous. The function of the aftercooler is to cool the high-temperature air at the outlet of the air compressor to below 40℃, condensing a large amount of water vapor and deteriorated oil mist into liquid water droplets and oil droplets, so that they can be eliminated.

Working principle: The air-cooled aftercooler uses the cold air generated by the fan to blow towards the heat pipe with heat dissipation fins to reduce the temperature of the compressed air. An automatic or manual drain should be installed at the lowest point of the aftercooler to drain the condensed water, oil droplets and other impurities.

Product features: No cooling water equipment is needed, and there is no need to worry about water shortage or freezing. It has a small footprint, light weight, compact structure, low operating cost, and easy maintenance, but it is only suitable for occasions where the inlet air temperature is below 100℃ and the amount of air to be processed is small.

Selection: Select the model of the aftercooler according to the system's operating pressure, the inlet air temperature of the aftercooler, the ambient temperature, the outlet air temperature of the aftercooler, and the amount of air to be processed.

Model parameters

| Model |

Processing capacity |

Power supply |

Power |

Pipe diameter |

Dimensions mm |

||

| Length (L) |

Width (W) |

Height (H) |

|||||

| DAC0005 |

0.8 |

220/50 |

100 |

G3/4" |

700 |

300 |

700 |

| DAC0010 |

1.8 |

220/50 |

120 |

G3/4" |

750 |

400 |

800 |

| DAC0030 |

3.8 |

220/50 |

150 |

G1" |

750 |

450 |

850 |

| DAC0060 |

6.8 |

220/50 |

250 |

G1 1/2" |

900 |

450 |

950 |

| DAC0080 |

8.8 |

220/50 |

300 |

G2" |

930 |

450 |

950 |

| DAC0120 |

14 |

220/50 |

380 |

G2 1/2" |

1380 |

550 |

1100 |

| DAC0150 |

16 |

380/50 |

500 |

G2 1/2" |

1500 |

600 |

1150 |

| DAC0250 |

28.5 |

380/50 |

1000 |

DN80 |

1600 |

600 |

1250 |

| DAC0300 |

35 |

380/50 |

1000 |

DN80 |

1500 |

650 |

1650 |

| DAC0400 |

45 |

380/50 |

1200 |

DN100 |

1600 |

700 |

1780 |

| DAC0500 |

55 |

380/50 |

1500 |

DN100 |

1680 |

750 |

1860 |