Applicable environment

-

Tools and instruments

Tools and instruments -

Control system

Control system -

Spraying tools

Spraying tools -

Injection successful

Injection successful -

Auto shop

Auto shop -

Tire pressure

Tire pressure

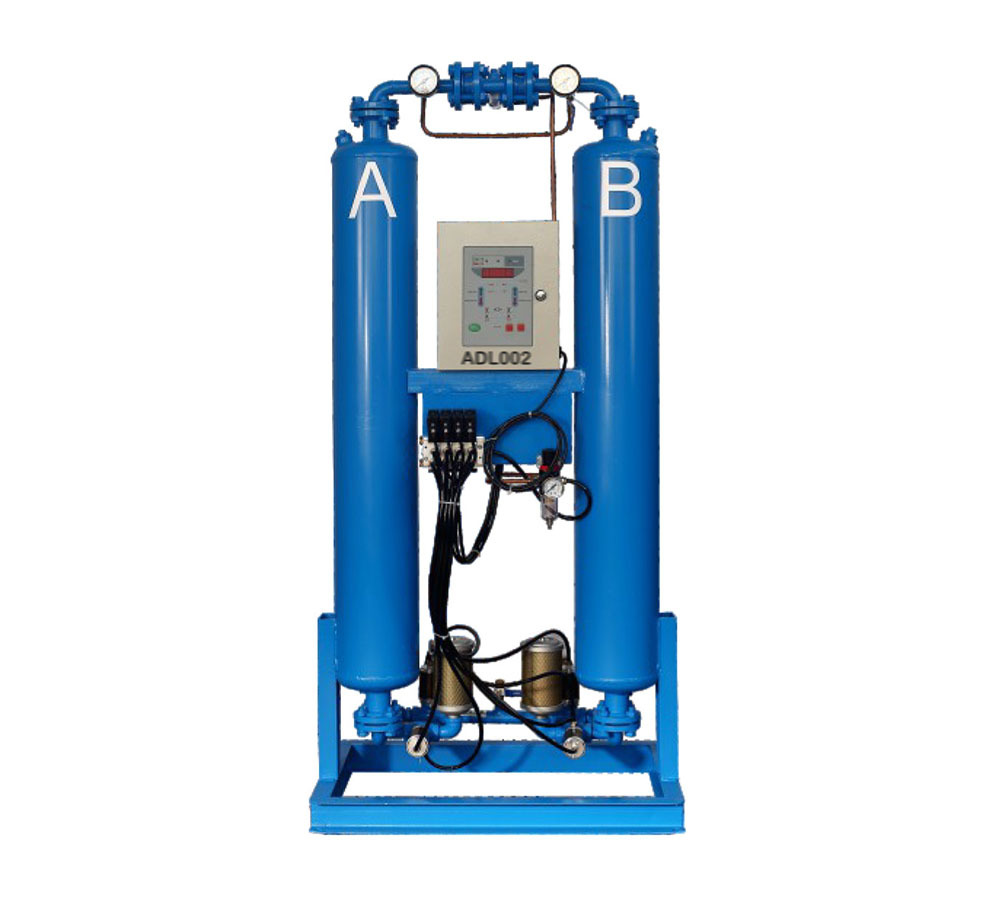

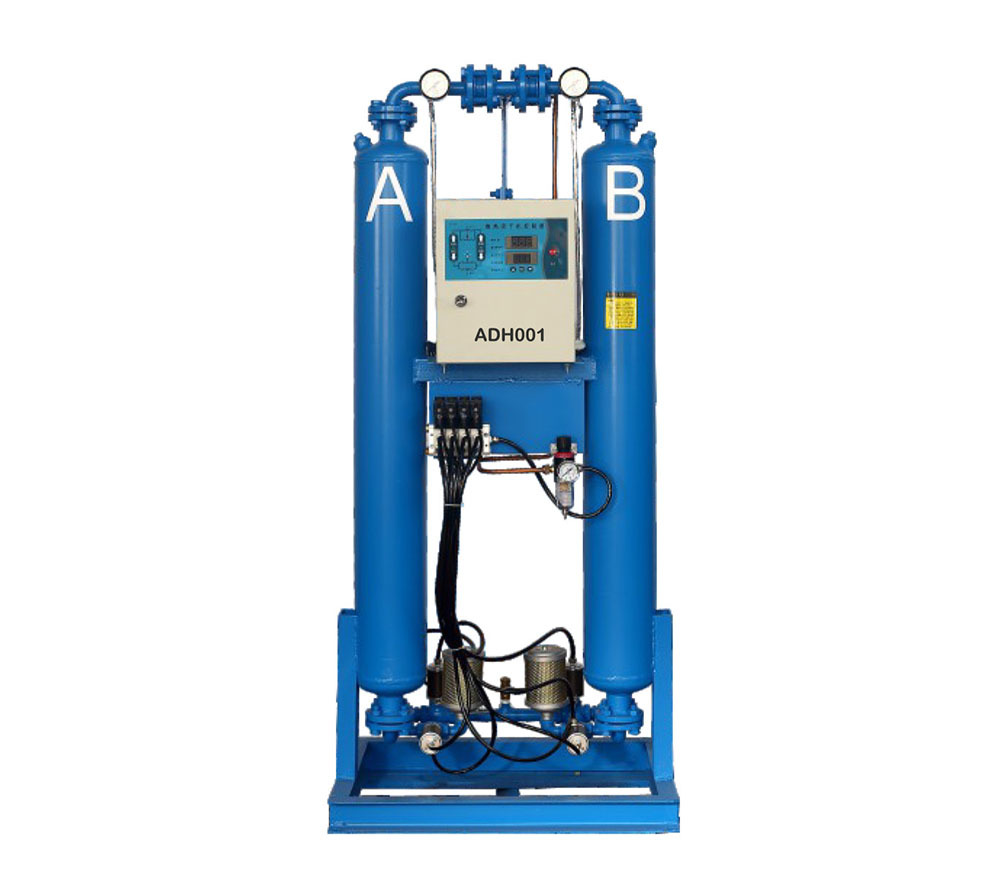

In adsorption drying equipment, the adsorbent is an important factor in ensuring the adsorption performance of the equipment. Adsorbents are generally substances with a large specific surface area and high porosity. Adsorbents should meet the following conditions: 1. Strong adsorption capacity, large specific surface area; 2. No chemical reaction with the adsorbate and other media in contact with it; 3. Good mechanical strength and heat resistance; 4. Easy to regenerate, not easy to deteriorate; 5. Can be mass-produced and low in price.

Currently, the adsorbents used in compressed air adsorption dryers include activated alumina and molecular sieves.

Activated alumina is dehydrated below 600℃ to produce a transitional state AI2O3, with a particle size of 3~7mm, white, high mechanical strength and heat resistance, does not soften, swell or crack when immersed in water, with a specific surface area of 300㎡/g, and has a high adsorption capacity. When used for compressed air drying, the water content per 1m³ of air can be reduced to 0.005g/m³, equivalent to a dew point of -64℃, and the regeneration temperature in the tower is 230~280℃. When the inlet temperature is 0~20℃, its adsorption effect is optimal, and it is a commonly used adsorbent for compressed air adsorption dryers.

Molecular sieve is a crystal with a cage-like pore skeleton composed of silicon (aluminum) oxygen tetrahedra. It is a high-efficiency and high-selectivity adsorbent with preferential adsorption capacity for polar molecules and unsaturated molecules. It has a particularly high affinity for water molecules. Drying gas with molecular sieves can generally achieve a dew point below -75℃, and it also has strong drying capacity for gases and liquids with high flow rates and temperatures. 13X and 4A type molecular sieves are commonly used, and their specific surface areas are all above 700m2/g.

The regeneration temperature of molecular sieves is relatively high. In industry, the regeneration temperature of molecular sieves is generally 150~300℃. If complete regeneration of molecular sieves is required to provide a dew point of -85~-100℃, the regeneration temperature is 315~375℃.

The disadvantages of molecular sieves are low mechanical strength and poor water drop resistance, and they are easily broken under pressure. When dealing with compressed air with high water load, it can be used in conjunction with alumina, that is, alumina is used for preliminary drying of compressed air, and then molecular sieves are used for deep drying of compressed air.

Adsorbent ceramic ball filler

Adsorbent molecular sieve filler

Adsorbent alumina filler

Molecular sieve

|

Index |

Unit |

Spherical |

Strip |

||

|

Diameter |

mm |

1.6-2.5 |

3-5 |

1.6 |

3.2 |

|

Static water adsorption |

≥mg/g |

270 |

270 |

270 |

270 |

|

CO2 adsorption |

≥mg/g |

180 |

180 |

180 |

180 |

|

Bulk density |

g/ml |

0.67±0.02 |

0.66±0.02 |

0.62±0.02 |

0.62±0.02 |

|

Compressive strength |

≥N |

30 |

80 |

30 |

65 |

|

Abrasion rate |

≤%wt |

0.1 |

0.1 |

0.1 |

0.1 |

|

Packaging water content |

≤%wt |

1.0 |

1.0 |

2.0 |

2.0 |

Activated alumina

|

Index |

Al2O3 |

SiO2 |

Fe2O3 |

Na2O |

Ignition loss |

Loose density |

Specific surface area |

Pore volume |

Crushing strength |

|

Technical |

≥93 |

≤0.10 |

≤0.04 |

≤0.45 |

≤7 |

≤0.75 |

≥280 |

≥0.40 |

≥30 1-2mm |

|

≥93 |

≤0.10 |

≤0.04 |

≤0.45 |

≤7 |

≤0.75 |

≥280 |

≥0.40 |

≥60 2-3mm |

|

|

≥93 |

≤0.10 |

≤0.04 |

≤0.45 |

≤7 |

≤0.75 |

≥280 |

≥0.40 |

≥100 3-5mm |

|

|

≥93 |

≤0.10 |

≤0.04 |

≤0.45 |

≤7 |

≤0.75 |

≥280 |

≥0.40 |

≥130 4-6mm |

|

|

≥93 |

≤0.10 |

≤0.04 |

≤0.45 |

≤7 |

≤0.75 |

≥280 |

≥0.40 |

≥160 5-7mm |

Tables 11-2 to 11-4 show a comparison of the various properties of activated alumina and molecular sieves, as given in reference [32].

11-2 Physical Properties of Common Adsorbents

|

Type of Adsorbent |

Density/(Kg/L) |

Mechanical Strength |

Thermal Conductivity/[W/(m.K)] |

Specific Heat Capacity/[J/(Kg.K)] |

Porosity (%) |

Average Pore Diameter/nm |

|

|

Bulk density |

True Density |

||||||

|

Activated alumina |

0.7~0.8 |

2.3~3.3 |

High |

0.130 6 |

1 045 |

45~50 |

40~50 |

|

Molecular sieve |

0.72 |

1.1 |

Limited |

0.588 9 |

752 |

45 |

4.8 |

11-3 Water Absorption/Dehydration Performance of Common Adsorbents

|

Type of Adsorbent |

Inlet Water Content (x10-6) |

Outlet Water Content (x10-6) |

Adsorption (%) |

TSA Regeneration Temperature/℃ |

|||

|

Static |

Dynamic |

Entering the Column |

Leaving the Column |

Highest |

|||

|

Activated alumina |

160~240 |

1~3 |

22 |

4~6 |

230~280 |

100~150 |

350 |

|

Molecular sieve |

160~240 |

1~3 |

22 |

8~15 |

320~370 |

120~200 |

475 |

11-4 Operating Conditions of Common Adsorbents

|

Type of Adsorbent |

Adsorption Capacity |

Water Droplet Stability |

Heat Resistance |

Alkaline Medium |

Acidic Medium |

Price |

|

|

Low Partial Pressure |

High Partial Pressure |

||||||

|

Activated alumina |

Low |

High |

Stable |

High |

Good |

Poor |

Relatively Expensive |

|

Molecular sieve |

High |

High |

Unstable |

High |

Good |

Poor |

Relatively Expensive |